Description

Equipment Description:

A dedicated automated device with high security and high precision, capable of conducting data traceability.

●High-precision positioning: The high-precision servo drive and visual positioning system are used to ensure that the position errors of key safety markings such as insulating sheets, nameplates, and QR codes, as well as functional stickers, are minimal.

●Safety-first design: Implement explosion-proof or spark-free designs in electrical control systems and pneumatic components, and possess excellent grounding and static electricity dissipation capabilities.

●Data traceability: It can be integrated with the scanning system to automatically link and associate the “cell/Pack code” with the “label code”, providing an accurate data source for the full lifecycle traceability of the product.

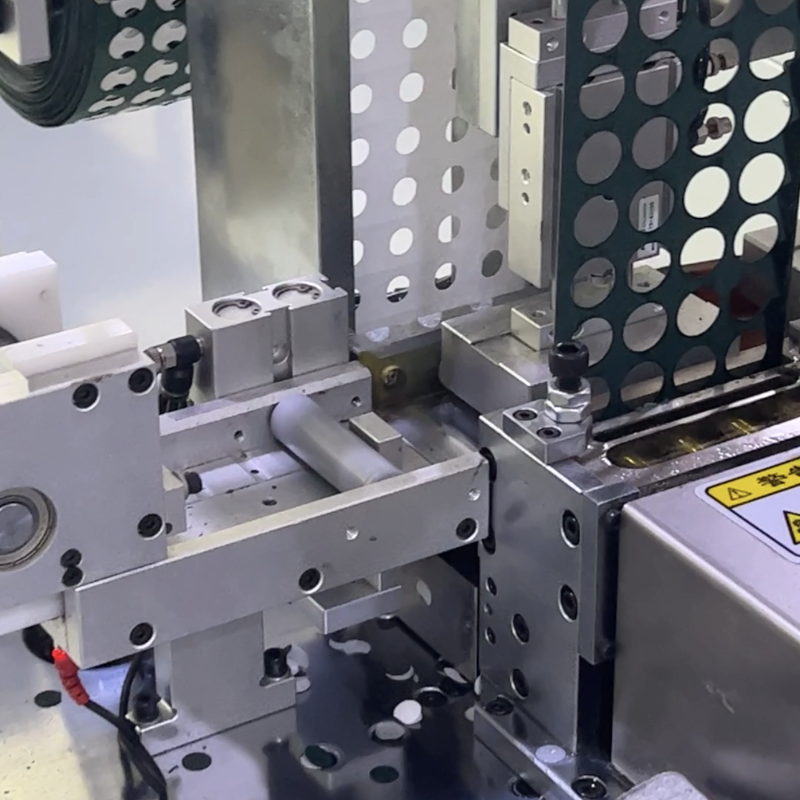

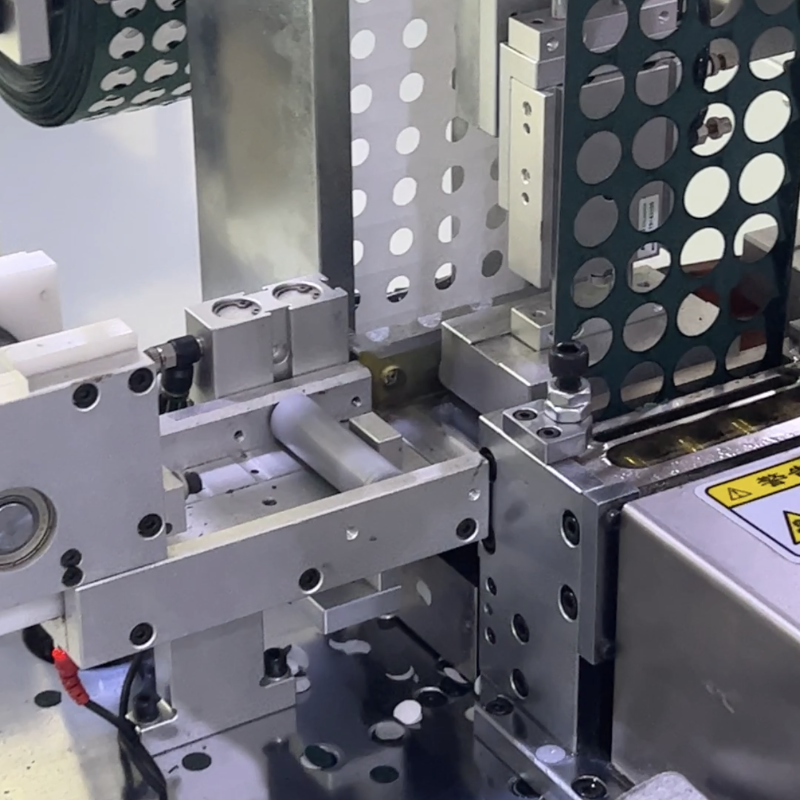

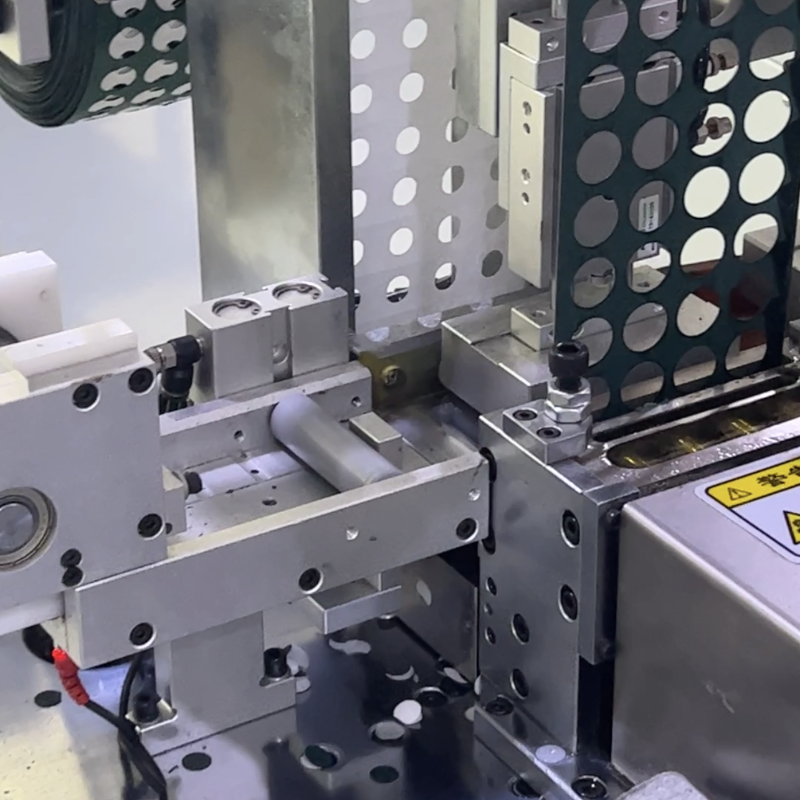

- This device is controlled by PLC to complete the function of pasting barley paper on the positive electrode of the finished battery cell, including stepper motor and cylinder.

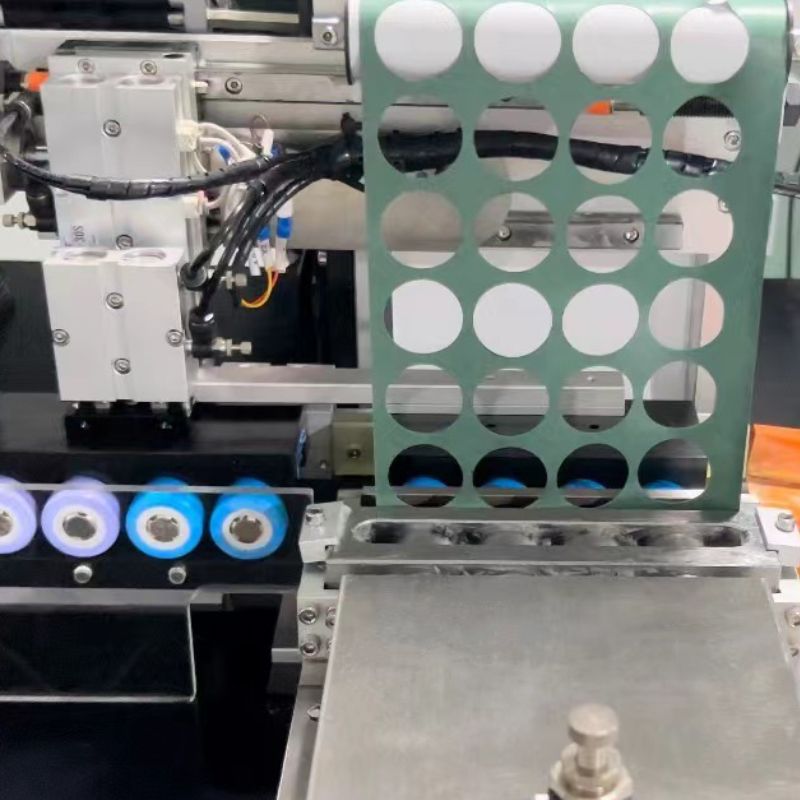

- Can be used for cylindrical steel shell cells such as 18650/21700/26650/32700 .

- Using a cylinder driven cutter for stamping, 4 battery cells are stamped at once. The slicing is made of high-speed steel material, which has high wear resistance, good product quality, and high production efficiency.

- High consistency of patch position and low defect rate.

- Fault information reminder function, fault sound and light alarm, can quickly diagnose faults.

- It has a tail material cleaning function and can be cleared with one click.

- Compatible materials: Highland barley paper, Kuaiba paper, glutinous rice paper, RET protective tape, etc.

- The mechanical structure design is simple and elegant, and the system performance is stable.

Technical Specs details presentation

| Main technical specifications | |

| Equipment capacity | 60-70PPM |

| Compatible with batteries | 18650-32700 |

| Stamping quantity | 3-4PCS |

| Sticker specifications | 17.5*10MM(18650) |

| Driving method | pneumatic |

| Control mode | Motion Controller |

| Size weight | 1275*860*1524MM 150KG |

| Power | 220V 50/60HZ |

Compatible with multiple types of battery cells

Suitable for various cylindrical batteries such as 18650/21700/26650/32700, this device can be used for multiple purposes and is easy to switch types.

Automatic waste recycling

Waste recycling + one-click tail-end waste removal function, easy maintenance, keeps the working area clean.

Cylinder-driven

The cutting tool is driven by a cylinder for stamping. The cutting tool is made of high-speed steel, which has excellent wear resistance and results in high product quality and high production efficiency.

PLC control

XJ PLC + Weilun touch screen, easy to operate, stable operation, low failure rate.

Reviews

There are no reviews yet.