Description

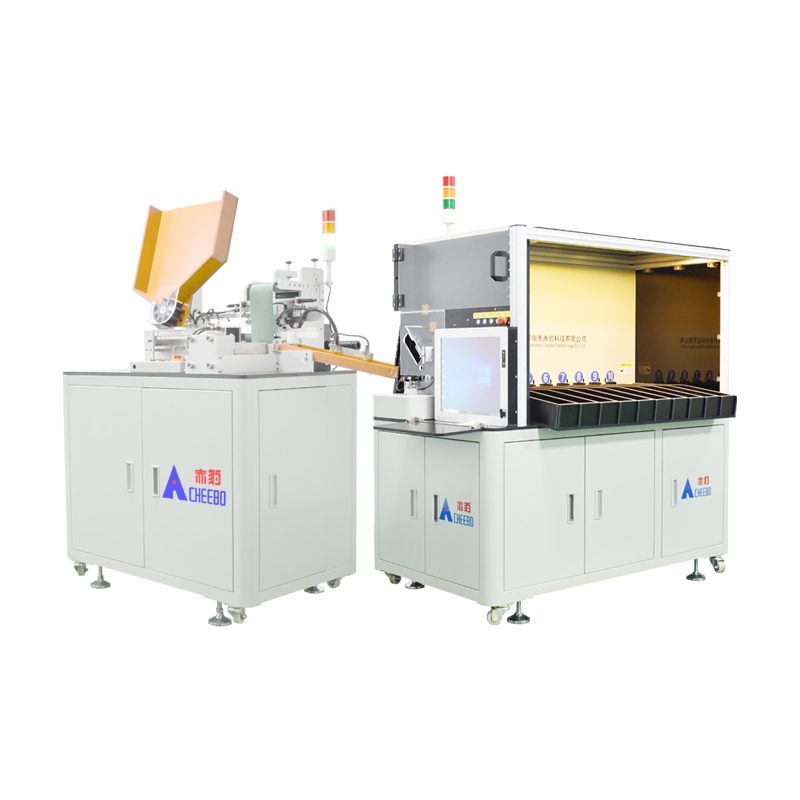

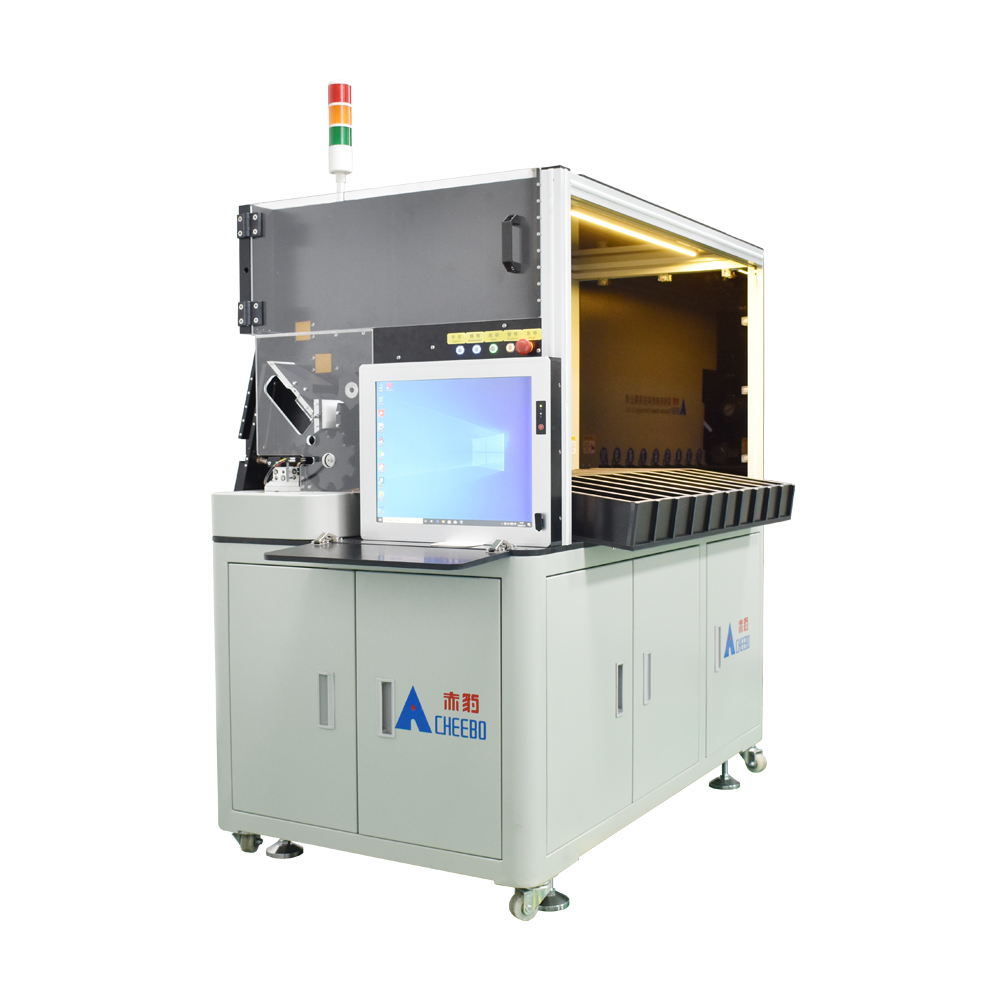

Equipment Description:

A highly intelligent production equipment that integrates three functions: automatic adhesion, visual inspection, and automatic sorting.

●Full-process closed-loop automation: As the workpiece passes along the production line, it automatically completes adhesion, 100% online inspection, and automatically sorts it into the storage or rejects based on the results, significantly shortening the process.

●High precision and zero defects: Equipped with high-performance industrial cameras and light sources, it can make real-time judgments on the position accuracy of the adhered products, appearance defects (dirt, scratches, bubbles, wrinkles), and whether there is any missed adhesion, ensuring that every product flowing out meets the standards.

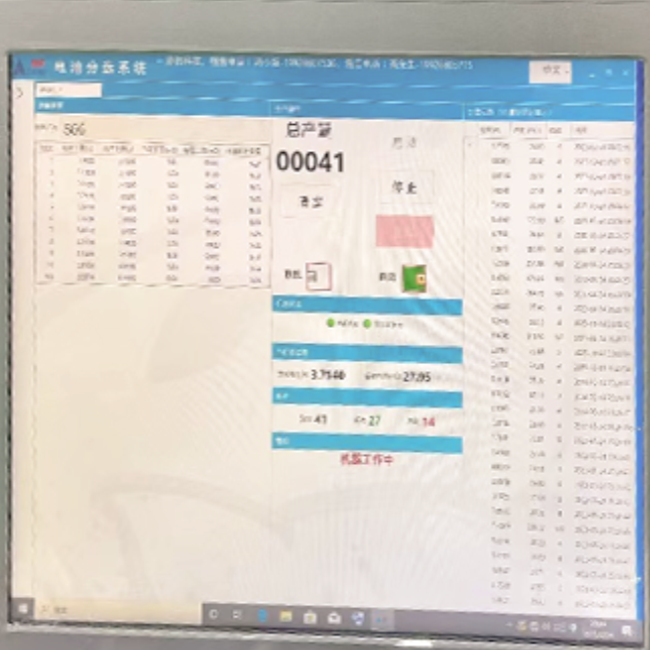

●Data-based traceability: Automatically records data such as production quantity, yield rate, defect types and distribution, and generates reports.

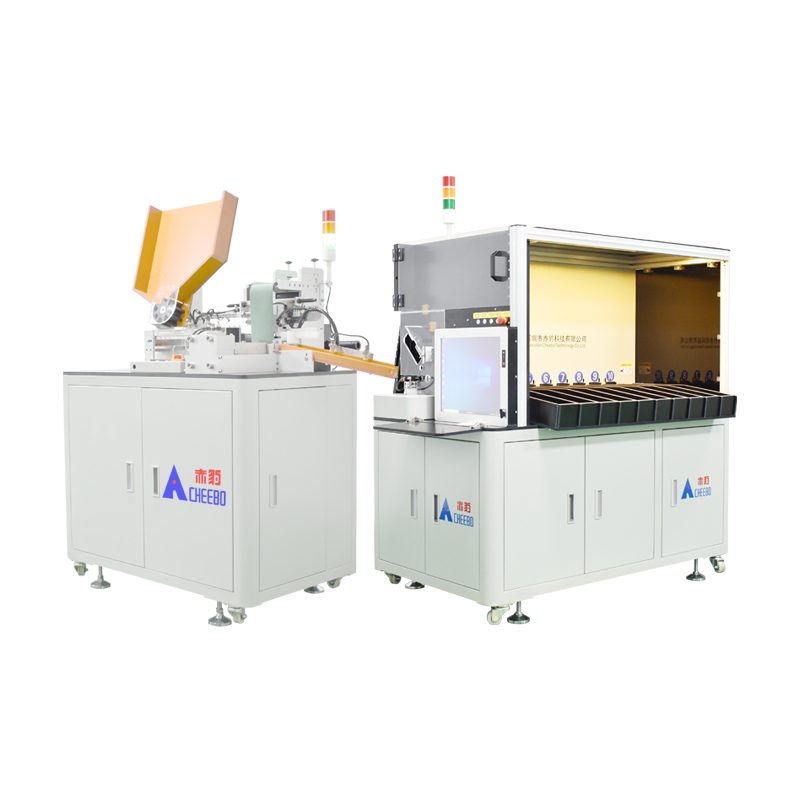

- Dual machine integration, high degree of automation, reduces intermediate links, and saves labor. Easy to operate, no need for professional person.

- Industrial control computer high-definition touch screen, easy to set parameters and record sorting parameters.

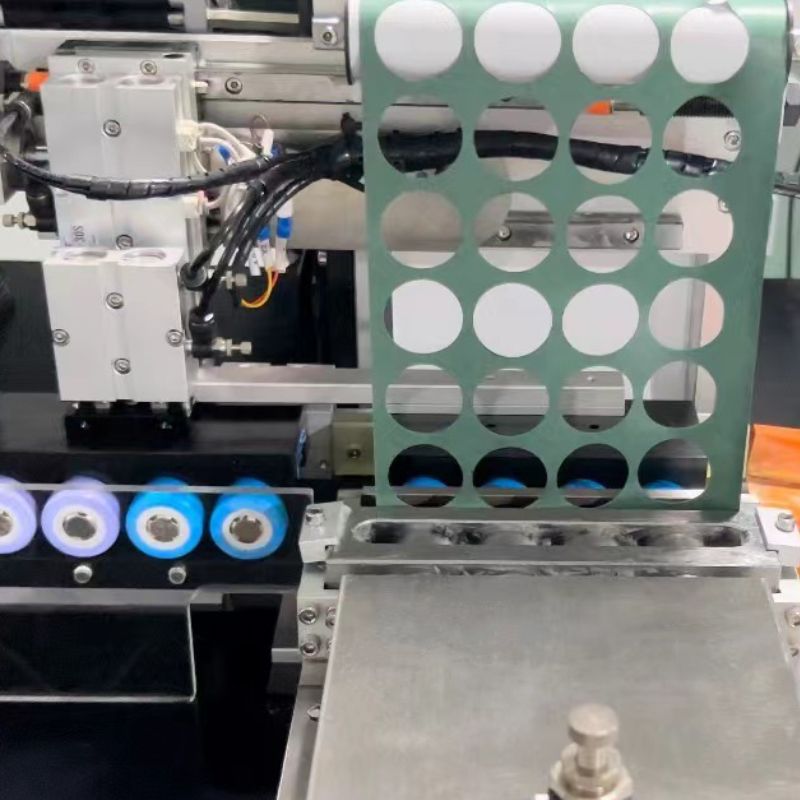

- The sorting machine adopts Mitsubishi PLC+imported Panasonic servo control unit+4 probe design, with stablel performance and long service life.

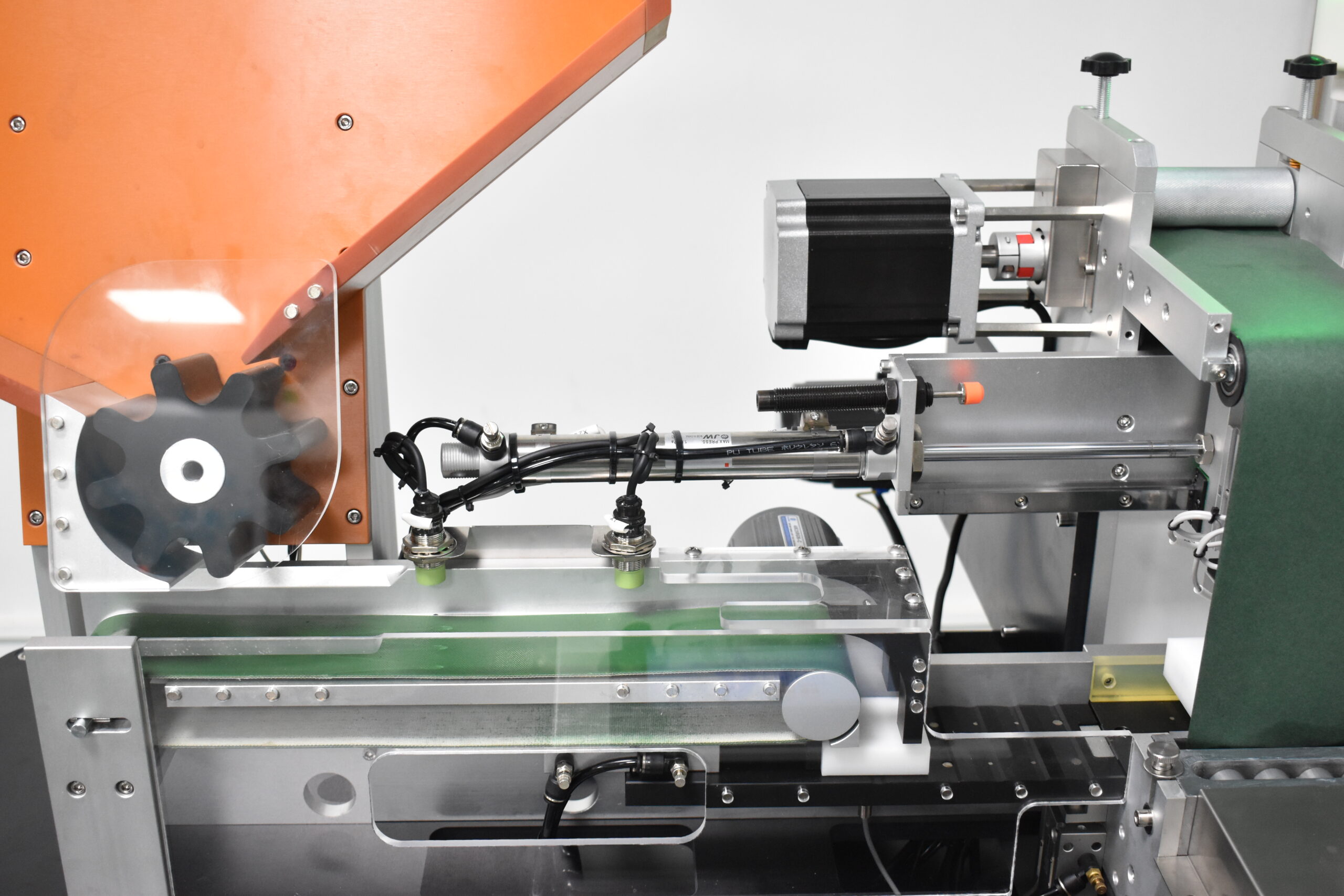

- The sticker machine uses a cylinder driven cutter for stamping, and the cutter is made of high-speed steel material with high wear resistance, good product quality, and high production efficiency.

- Independently develop various automated intelligent systems to facilitate device operation and help improve production efficiency.

- Aluminum alloy structure, electrostatic powder coating process, scratch resistant, rust proof, anti-static.

- Imported acrylic protective board, beautiful and stylish with strong technological sense, visual operation improves production safety factor.

Technical Specs details presentation

| Main technical specifications | |

| Equipment capacity | 60-70PPM |

| Compatible with batteries | 18650-32700 |

| Stamping quantity | 3-4PCS |

| Sorting gear | 10+1 |

| Tester | HIOKI/HEPU |

| Sort parameters | Open circuit voltage, AC internal resistance |

| Driving method | pneumatic |

| Power | 220V 50/60HZ |

Dual-computer integration

Reduces intermediate steps and saves manpower. Simple to operate, no need for professionals.

Multi-axis control board card

The sorting machine adopts a multi-axis linkage motion control board card with higher precision + 4 probe design, featuring stable performance and long service life.

Touchscreen display

High-definition touch screen, easy to set parameters and record sorting parameters, and the data can be retrieved after sorting.

High-precision positioning system

Repositioning accuracy: 0.1mm. The sticker positions are consistent. The pass rate is ≥ 99%.

Reviews

There are no reviews yet.