Description

Equipment Description:

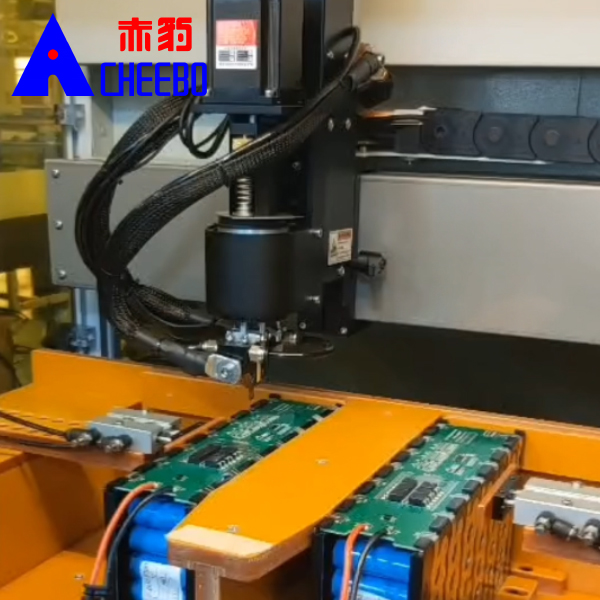

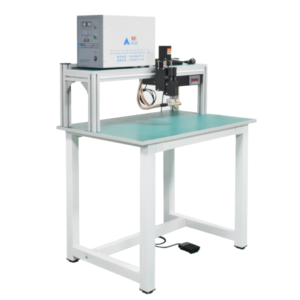

An intelligent, automated, high-performance industrial lithium battery welding machine

● High load rate: It features an extremely high load duration rate, enabling long-term and stable high-current welding without easily shutting down due to overheating.

● High quality: A single module is adopted, which avoids the problem of uneven current distribution caused by slight parameter differences when multiple tubes are connected in parallel. It operates stably and has a longer lifespan.

● High precision: Regardless of whether it is a high current or a low current, the arc is extremely concentrated, flexible and stable. It responds extremely quickly to short circuits and droplet transition, and can achieve more precise waveform control.

- It can work on both left and right platforms without interfering with each other,or only use a single platform.

- Suitable for nickel plating process BMS welding, one machine dual-use.

- 135°electric precision rotating welding head, suitable for various shaped nickel sheets,with anti sticking needle function.

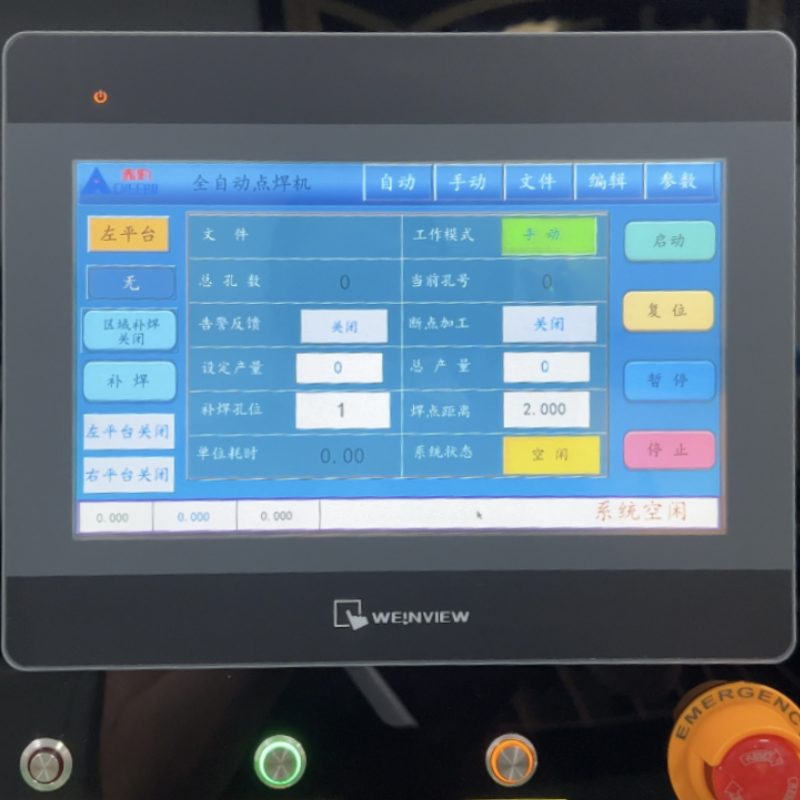

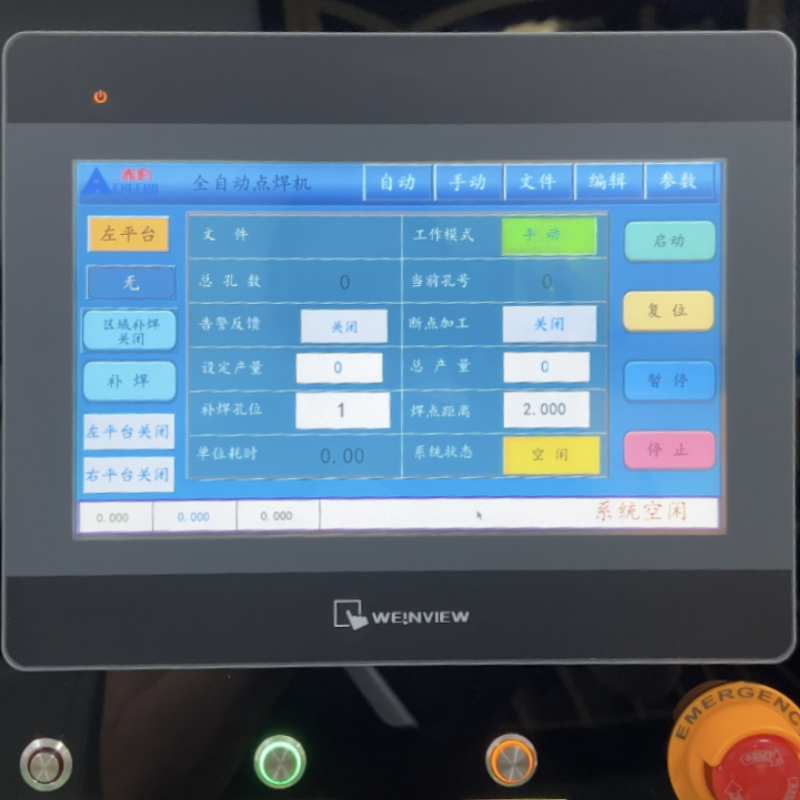

- Explosion welding and weak welding equipment automatically alarm, manual adjustment of automatic area welding repair, single point welding repair.

- Manual programming, CAD mapping, importing spot welding paths, easy to learn and quickly implement programming.

- Independently develop various automated intelligent systems to facilitate device operation and help improve production efficiency.

- Equipped with energy switching function, production counting function, welding needle compensation function, manual debugging function, etc.

- Imported acrylic protective board, beautiful and stylish with strong technological sense, visual operation improves production safety factor.

Technical Specs details presentation

| Main technical specifications | |

| Equipment capacity | 30-40PPM |

| Compatible Battery | 18650–33140 |

| Compatible Modules | <600*400MM(Customizable) |

| Welding thickness | 0.02-0.3MM |

| Repositioning accuracy | ±0.01 |

| Welding head rotation angle | 0~135° |

| Welding power source | Transistor/Multi pulse |

| Weld pressure | 5KG/F(Adjustable) |

| Cooling method | Water circulation cooling |

| Driving method | pneumatic |

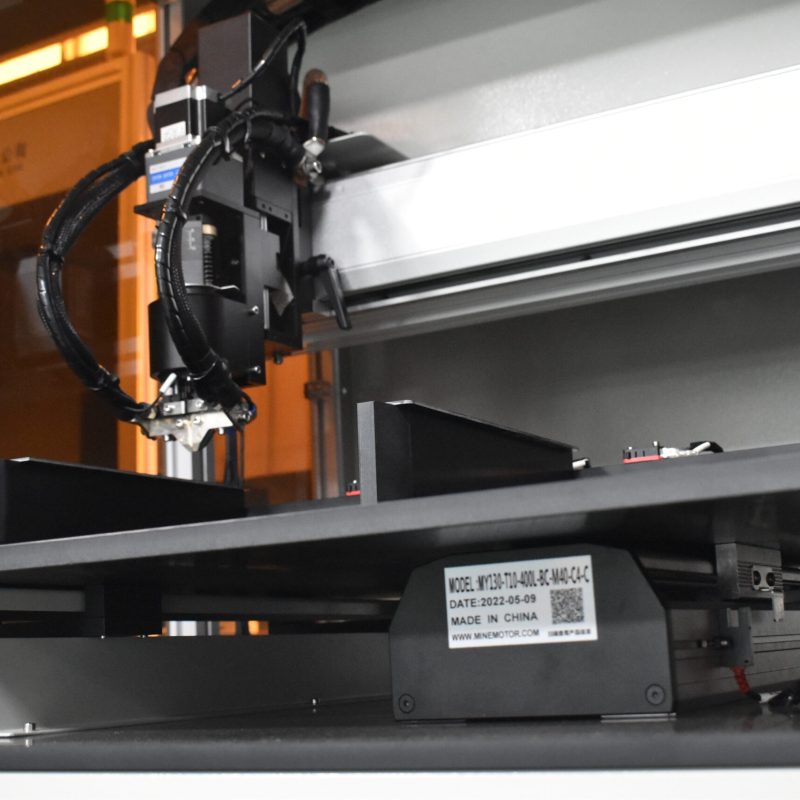

| Size weight | 1400*1000*1680MM 380KG |

| Power | 220V 50/60HZ |

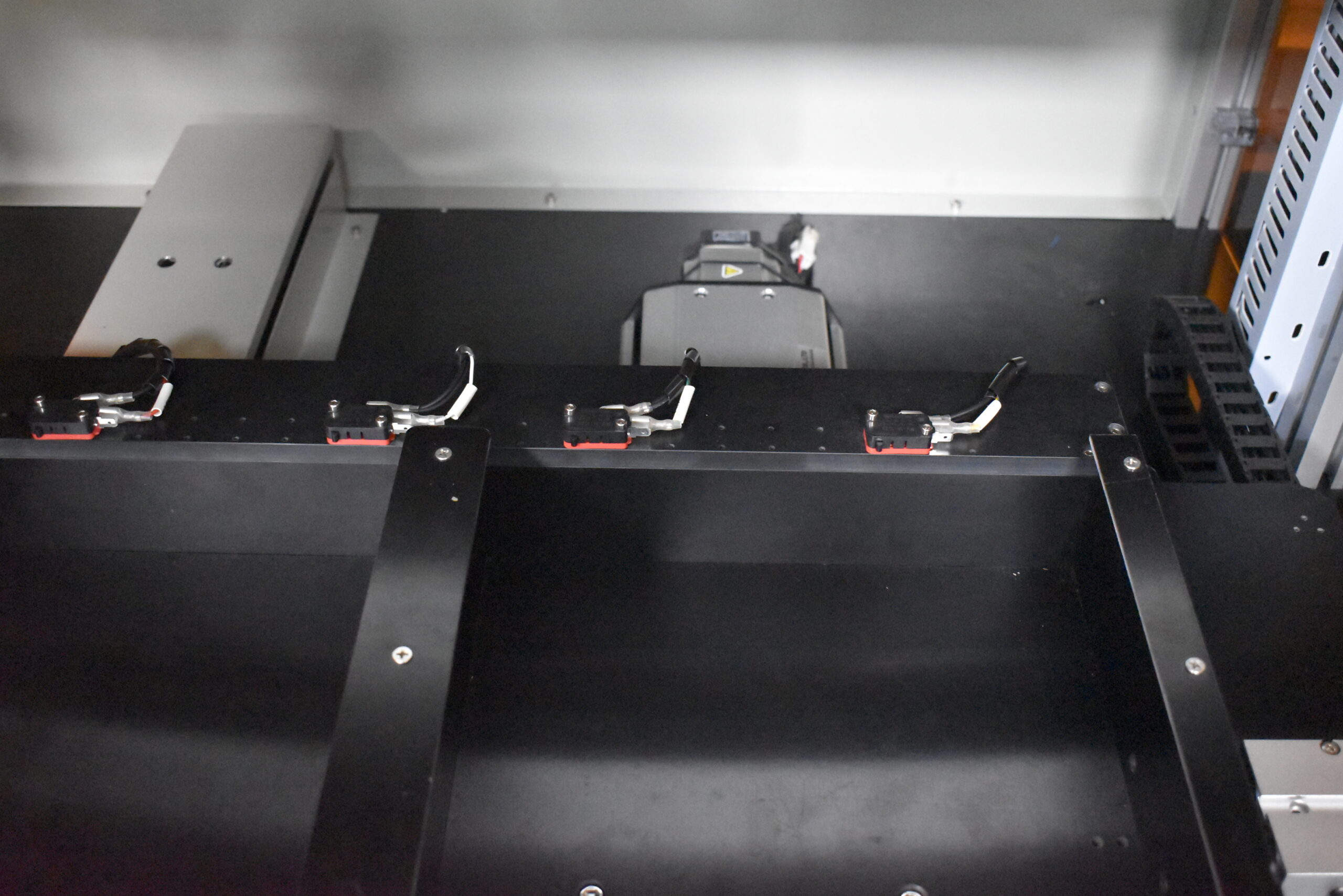

Dual-platform independent operation

Left and right platforms can run simultaneously or independently without interference, supporting non-stop material changeover for high production efficiency.

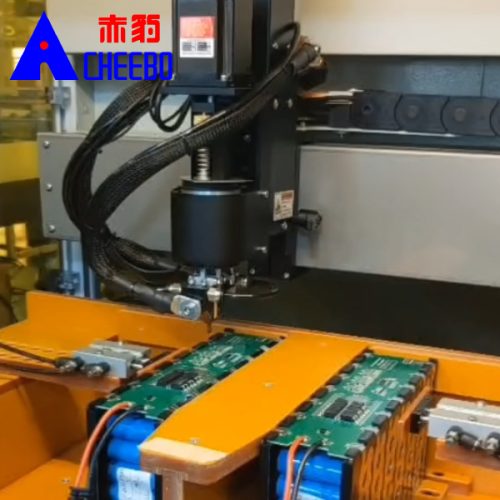

Rotating welding head

Our independently developed 135° rotating welding head is ideal for welding irregular nickel plates. Pure nickel construction prevents needle sticking. Welding pressure is precisely adjustable via a buffer spring pressure adjustment mechanism, effectively minimizing damage to battery cells.

Dual-purpose machine

Spot welding battery packs/BMS. By customizing the corresponding fixtures, the model can be changed for welding.The minimum should not be lower than 50MM, and the maximum should not exceed 144MM.

Intelligent Programming Operation

Supports CAD path import, manual programming, and computer programming. Stores up to 190 welding recipes for flexible and efficient operation.

Reviews

There are no reviews yet.