Description

Equipment Description:

The automation process from component to finished product in lithium battery packs has significantly enhanced production efficiency and product consistency.

● Full-process automated production

It integrates all assembly processes from cell loading, labeling, scanning, sorting and testing to assembly, CCD inspection, and welding.

●High degree of customization and flexibility

Carry out customized design and processing based on the different battery pack types and specific requirements of the customers.

●Support “One Line for Multiple Uses”

It has excellent compatibility and can be used to assemble multiple different types of battery packs on the same production line.

- The entire line is compatible with 18650/21700/26650/32700 cylindrical battery assemblies.

- Cell loading: robotic gripper cell automatic loading, modular design, compatible with diferent models of battery cell

- Cell sticker: PLC control stepping motor and air cylinder to complete the positive pole ofthe cell sticker barley paper

- Cell sorter: with the code scanning function, automatically detect the voltage of the cell,internal resistance for sorting.NG excluded from the file.

- CCD detection: machine vision technology based on CcD industrial camera to detect the positive and negative poles ofthe battery cell, to determine the polarity of the battery pack OK/NG

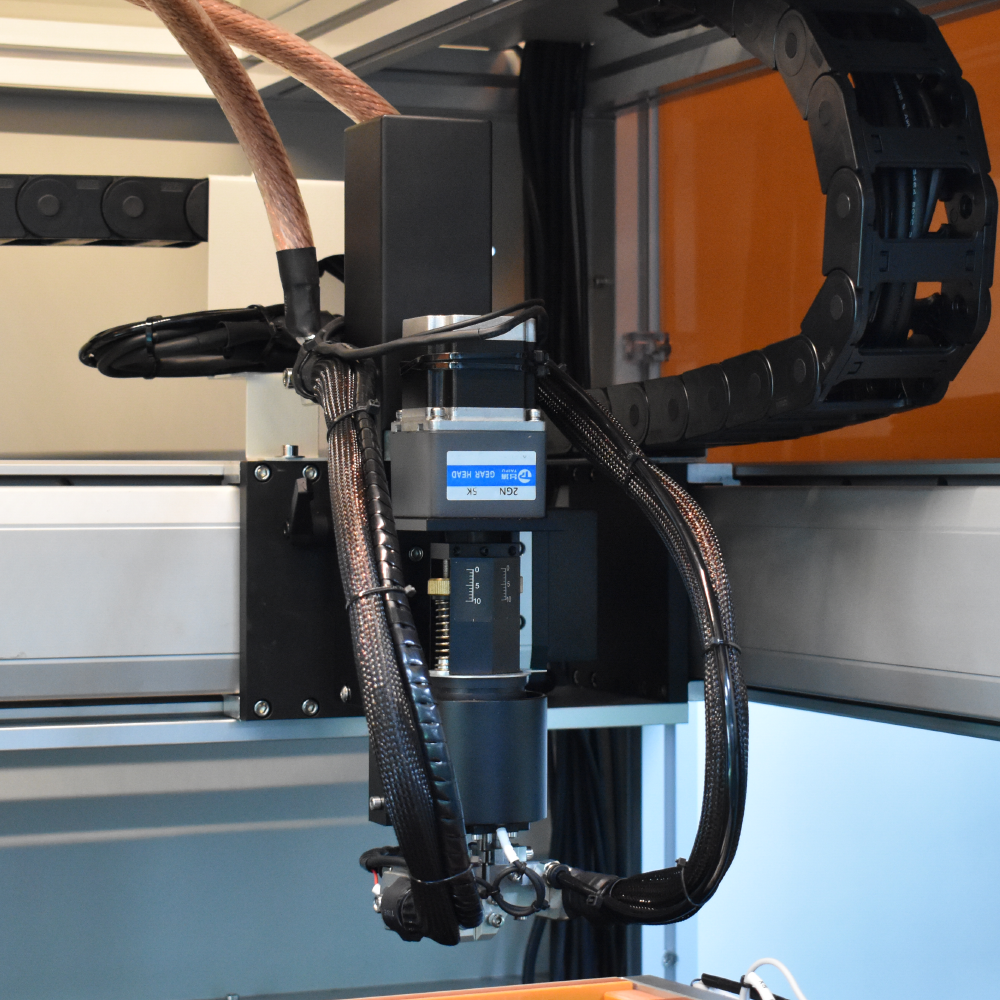

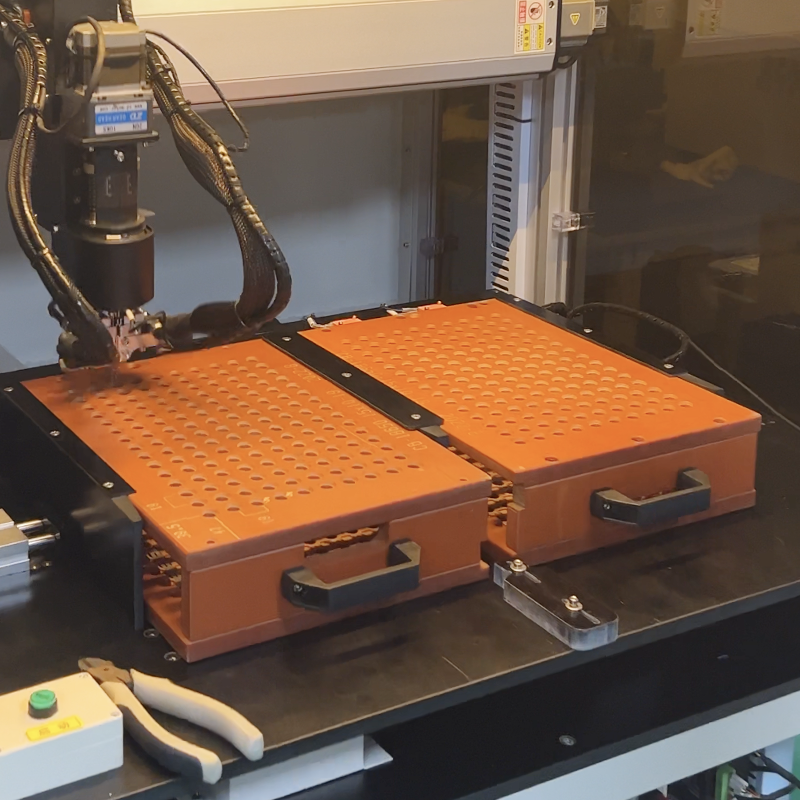

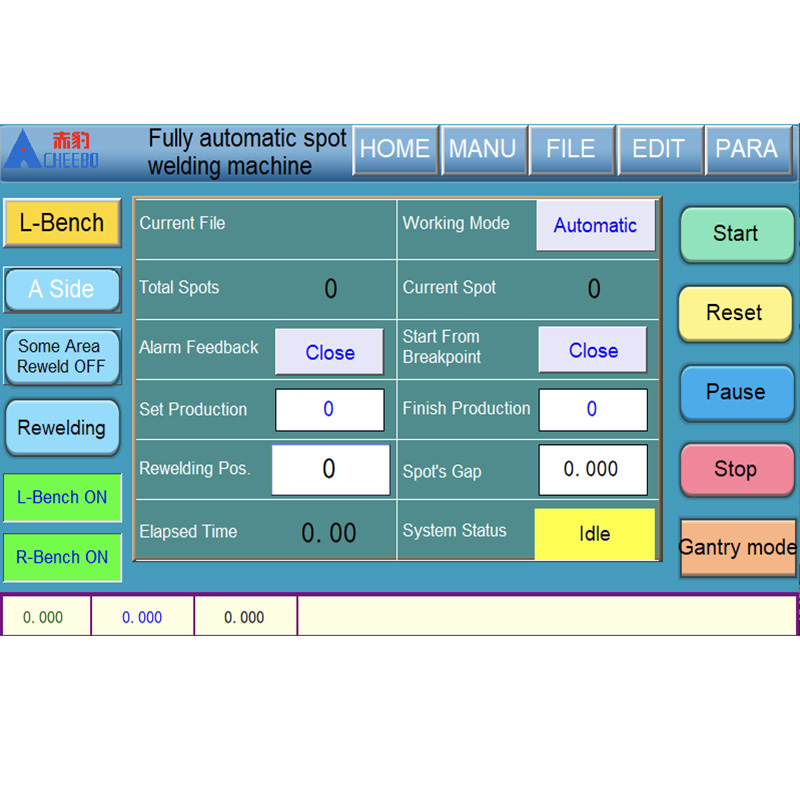

- Spot welder: high precision power supply, electric precision rotary welding head, with professional and mature weldingtechnology,realize high quality and efficient welding.

- Flip mechanism: using modular integration technology, flip the battery pack after welding to weld the reverse side

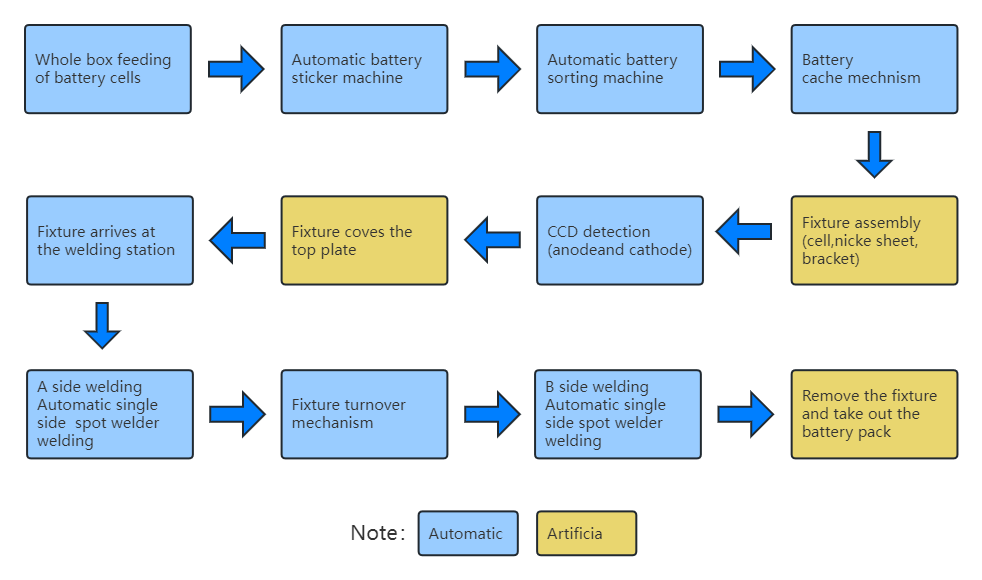

Process Flow Diagram

Technical Specs

| Equipment capacity | 40-50PPM |

| Compatible Battery | 18650–33400 |

| Compatible Modules | <750*500MM(可定制) |

| Qualification rate | ≥99% |

| Crop rate | ≥98% |

Details presentation

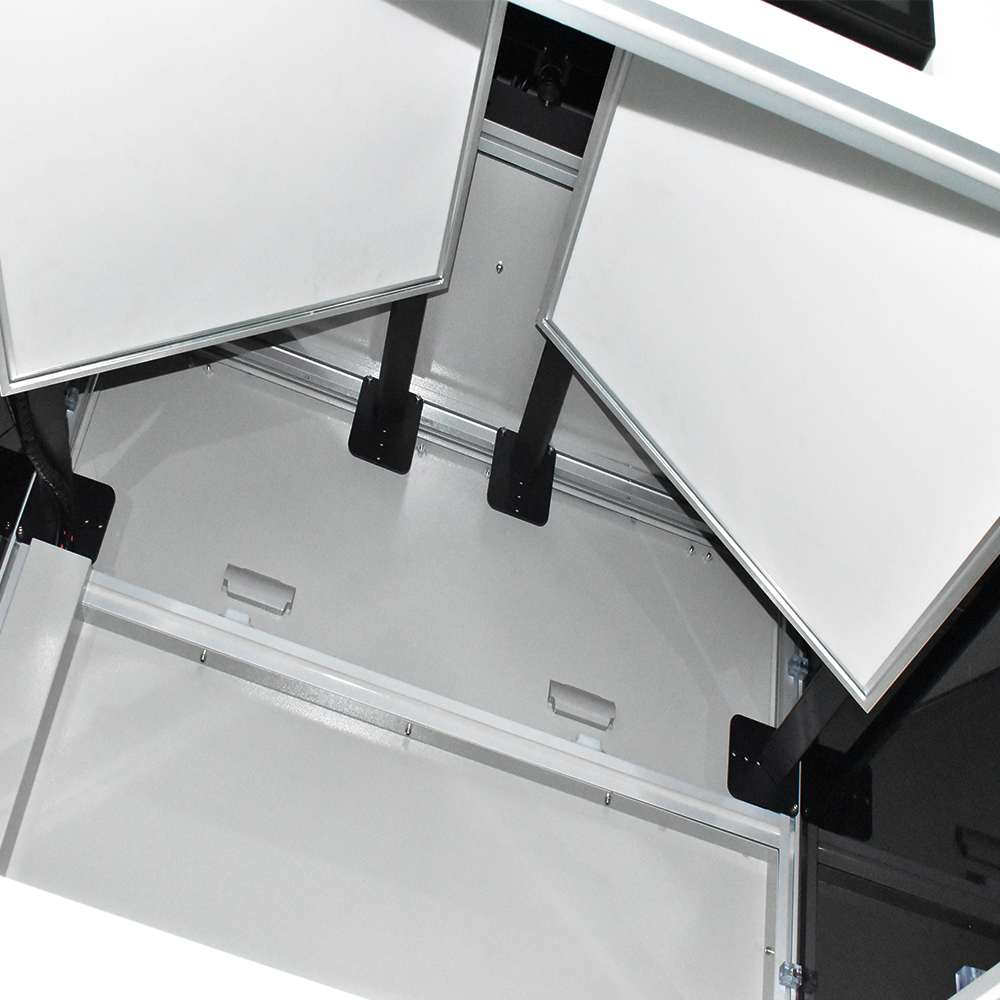

Battery sticker machine

The cylindrical battery is automatically covered with barley paper. It is controlled by PLC and touch screen, which is easy to operate and runs stably.

Battery polarity detection

In the assembly process of the battery pack, visual inspection of the positive and negative electrodes of the batteries is carried out using a 20-megapixel Hikvision industrial camera. High detection accuracy, supporting positioning, comparison and other types of defect recognition.

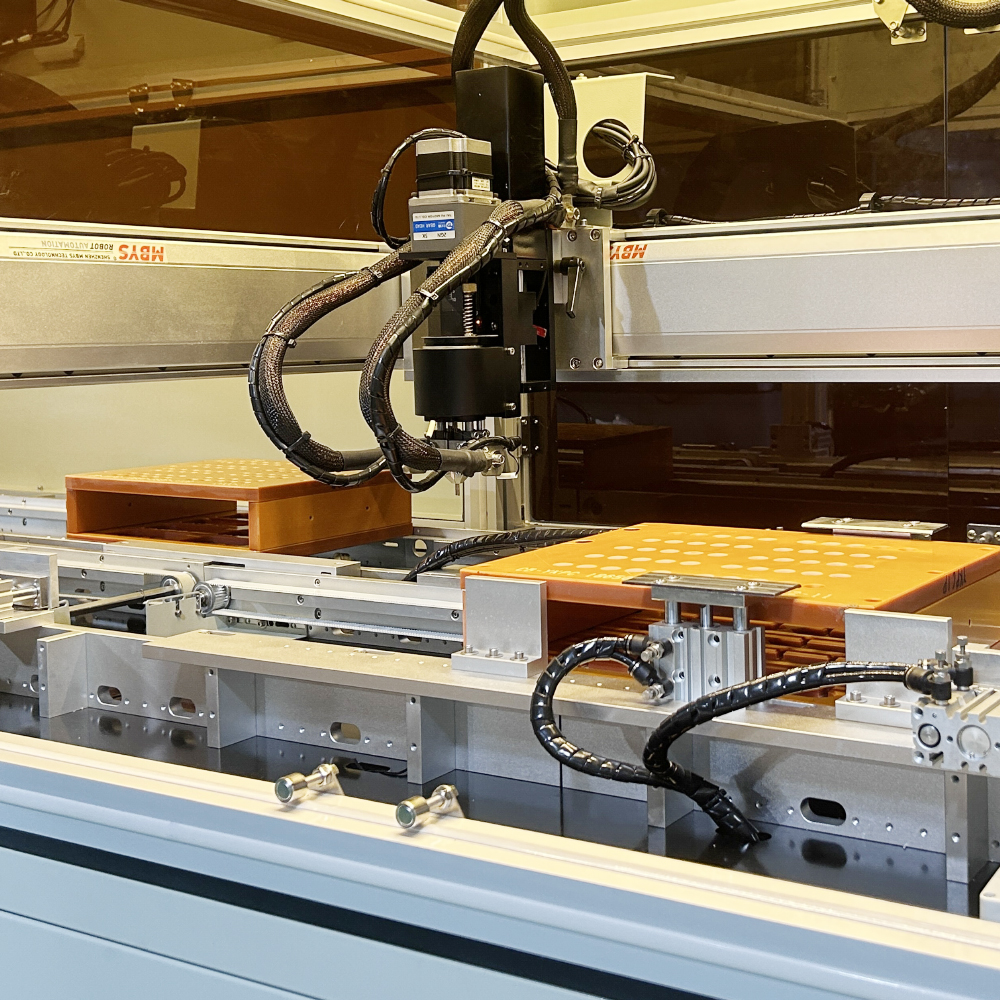

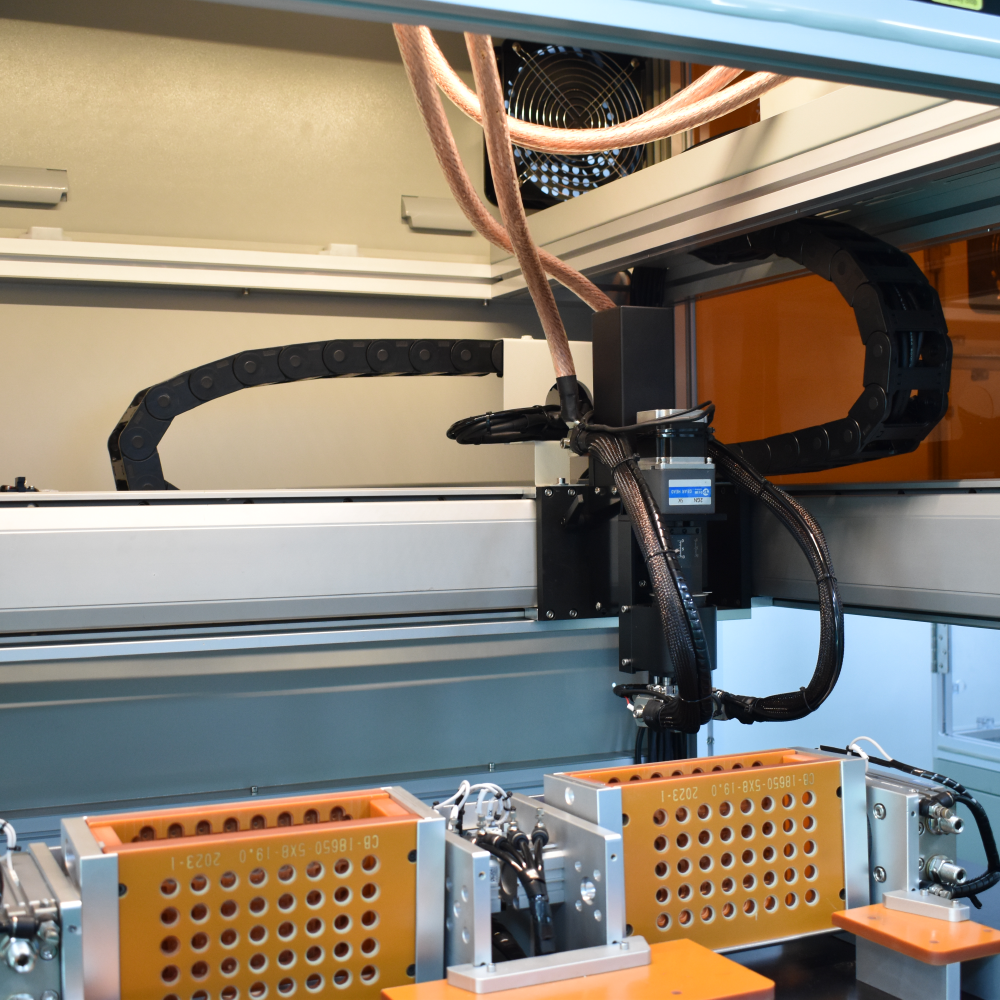

Sopt welding

Utilizing modular integration technology, the battery is flipped for welding the B-side after completing the A-side welding. Single-side welding enhances weld quality, while the flipping mechanism boosts production efficiency.

Cell sorting mechanism

The industrial control computer displays real-time sorting data, supports query, saving and export functions, facilitating analysis and traceability.

Reviews

There are no reviews yet.