Description

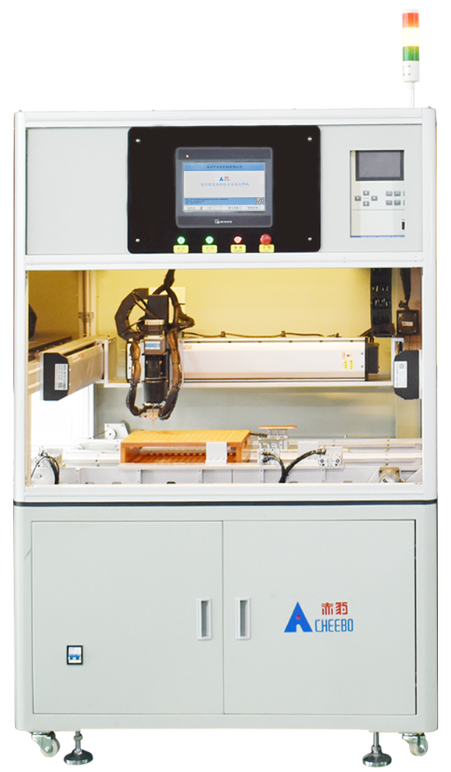

Equipment Description:

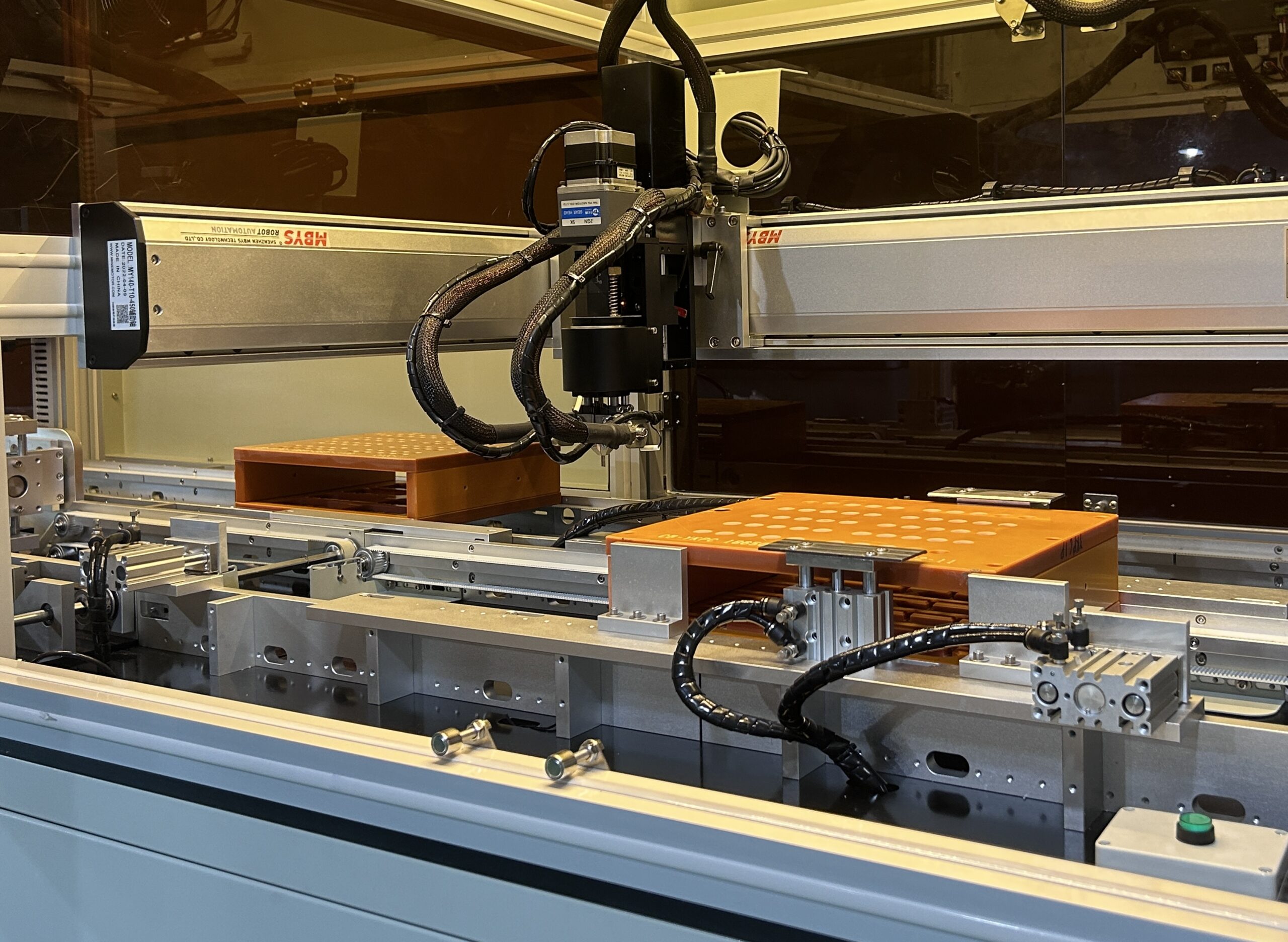

An advanced welding production line with highly automated single-sided welding and double-sided forming process.

● High efficiency: The assembly line process design, with a reflow mechanism built into the welding line, eliminates the need for flipping the workpieces, enabling continuous automated production.This significantly enhances operational efficiency and greatly reduces the need for human labor.

● High quality: The weld formation is stable and consistent, the back weld is aesthetically pleasing, and it reduces the subsequent processing steps.

● Easy to automate: The process is stable and the parameters are fixed, making it suitable for integration with specialized machines to form an intelligent production line.

- The use of assembly line structure design,maximize labor savings.

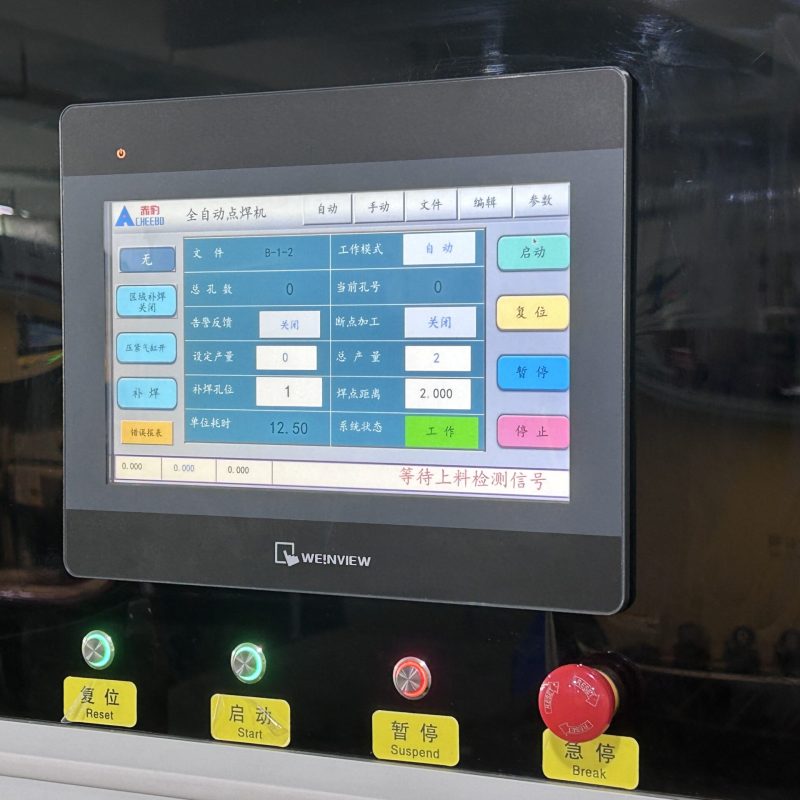

- Manually write the program and computer program,welding path according to the program set path welding.

- A 135° rotating welding head, suitable for welding of dissimilar nickel sheets. Pure nickel is anti-stick. The welding pressure can be adjusted precisely. The pressure regulating mechanism with a buffer spring can effectively reduce the damage to the battery cells.

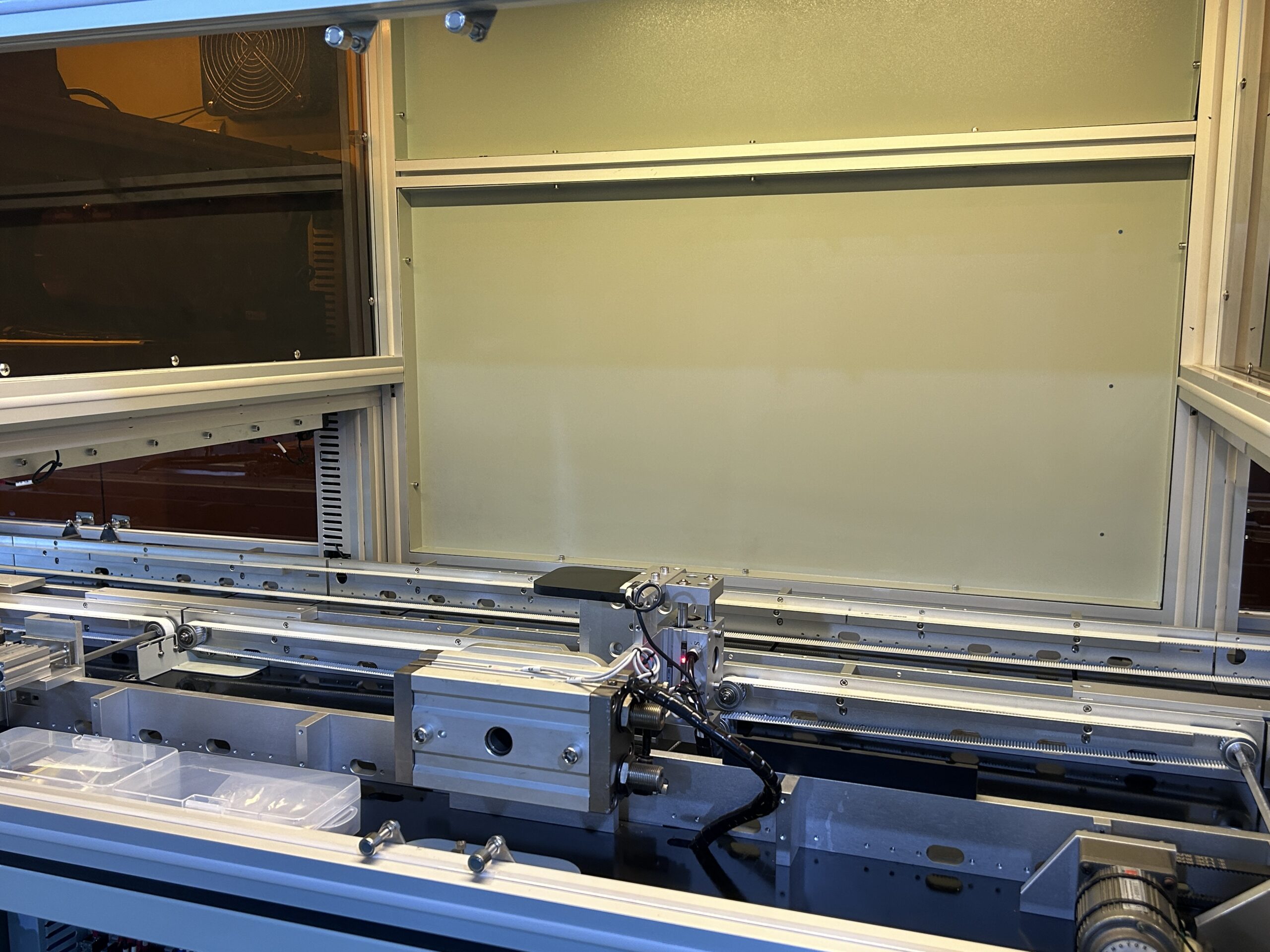

- Transparent workstation design structure,which is conducive to timely observation and understanding of the welding situation.

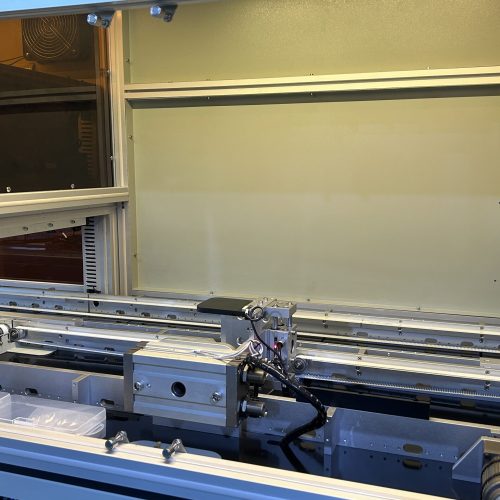

- The backend adopts modular integration technology to flip and weld the B side of the battery after the A side welding is completed. Single-sided welding enhances the welding quality, while the flipping mechanism increases production efficiency.

Technical Specs details presentation

| Main technical specifications | |

| Equipment capacity | 50-60PPM |

| Compatible Battery | 18650–32700 |

| Compatible Modules | <250*400MM(Customizable) |

| Welding thickness | 0.02-0.3MM |

| Repositioning accuracy | ±0.01 |

| Welding head rotation angle | 135° |

| Cooling method | water cooling |

| Driving method | Pneumatic |

| Qualification rate | ≥99% |

| Crop rate | ≥98% |

| Welding power source | Transistor/Multi pulse |

| Qualification rate | ≥99% |

| Crop rate | ≥98% |

| Power | 220V 50/60HZ |

Single-sided automated welding

Utilizing modular integration technology, the battery is flipped for welding the B-side after completing the A-side welding. Single-side welding enhances weld quality, while the flipping mechanism boosts production efficiency.

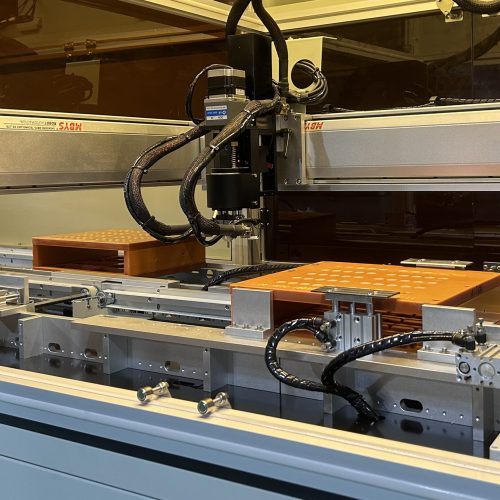

Rotating welding head

The 135° rotating welding head is highly suitable for welding irregular nickel plates. The pure nickel material can prevent the needle from getting stuck. The welding pressure can be precisely adjusted through the buffer spring pressure regulation mechanism, effectively reducing damage to the battery cells.

Automatic reflow mechanism

The reflow mechanism is integrated within the welding line. The welding fixtures can be automatically transported to the previous assembly station, thereby saving labor and enhancing work efficiency.

Intelligent Programming Operation

Supports CAD path import, manual programming, and computer programming. Stores up to 190 welding recipes for flexible and efficient operation.

Reviews

There are no reviews yet.