Description

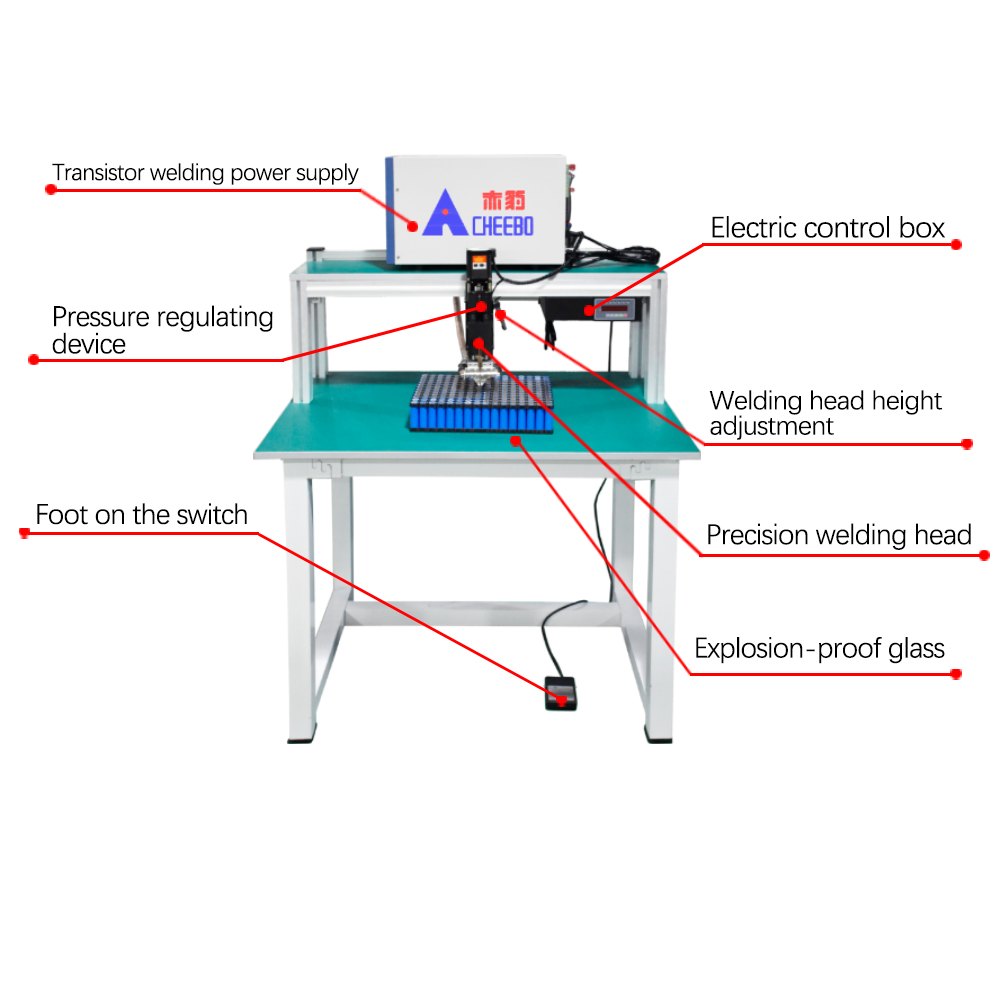

Equipment Description:

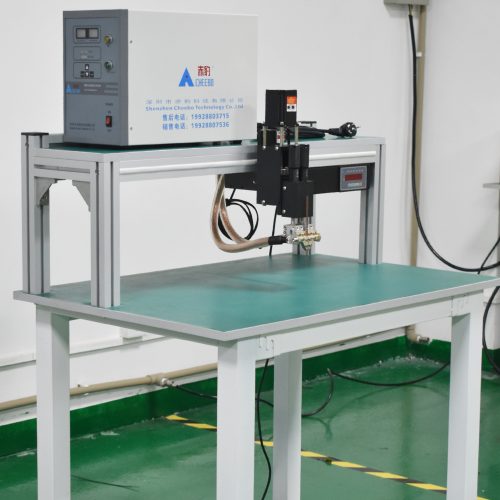

●High stability: Utilizing a sturdy C-type or gantry-style integral frame, the welding needle pressure is adjustable and stable. The downward pressure is fast, significantly increasing the welding cycle.

●High precision: The precise linear guide rails ensure that the up-and-down movement trajectory of the welding head is extremely accurate and vertical. Each welding point has consistent pressure and the weld core position is accurate.

●High convenience: Using a stepper motor drive, no external air pipe is required. Just connect to the power supply and it can be used. The noise is low.

- Pure electric without cylinders, low noise, stable pressure. (Electric)

- Motor driven, precise control box, three adjustable modes. (Electric)

- Independently developed precision welding machine head, with precise pressure adjustment and control.

- Exclusive output energy optimization algorithm, reasonable conversion of output voltage and output current,

- Microcomputer technology control, control voltage grid, automatic tracking compensation.

- Vertical spot welding method is used for spot welding, with manual control of the pressing depth.

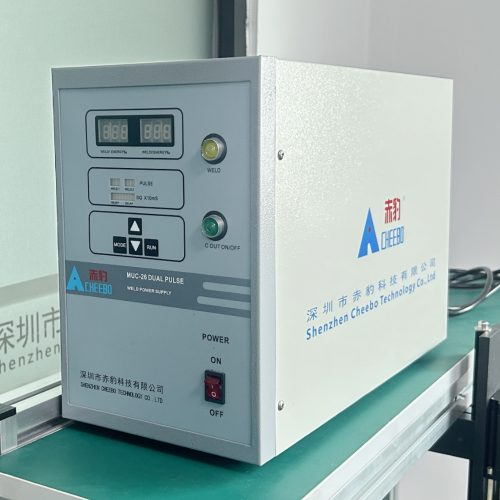

- Digital LED display makes the adjustment of various parameters of the device more intuitive, easy to learn and operate.

- The welding machine can pre store multiple programs, which can be changed or called at will.

- Compact structure, small volume, high power, large industrial circuit design, safe and reliable welding process.

Technical Specs details presentation

| Main technical specifications | |

| Drive mode | Electric, pneumatic (optional) |

| Welding thickness | 0.04-0.2mm |

| Welding method | Single side horizontal welding |

| Welding power supply | Multi pulse |

| Power supply current | 3000A/5000A/8000A/10000A/13000A |

| Equipment power | 12KW/7KW |

| welding speed | 100P/M (maximum) |

| Welding pressure | 5KG/F (adjustable) |

| Welding height | <250MM |

| Size and weight | 900*600*1300mm 70KG |

Multi-pulse welding power supply

Multi-pulse regulation can improve the waveform of the welding output power, enhance the welding capacity, and result in strong and aesthetically pleasing weld points.

No air source required (electric model)

Driven by a stepper motor, eliminating the need for an external air pump. Plug and play with low noise operation.

3 Operation Modes (Electric Model)

Supports single-point, semi-automatic, and fully automatic modes to accommodate varying production rhythms.

Precision Welding Head

Features precisely adjustable welding pressure and a buffer pressure adjustment mechanism to effectively minimize damage to battery cells during welding.

Reviews

There are no reviews yet.