Description

Equipment Description:

The fully automatic single-sided spot welding machine is a highly integrated advanced manufacturing equipment.

●Fully automatic: From the entry of raw materials or semi-finished products into the workstation to the output of the finished products after welding, the entire process does not require direct human intervention. Operators are only responsible for monitoring, replenishing materials, and maintenance.

●High output: Under the premise of ensuring maintenance, it can achieve uninterrupted production, greatly enhancing equipment utilization and total output.

●Adaptive adjustment: It can automatically fine-tune welding parameters according to electrode wear, grid fluctuations and other conditions to ensure the stability of long-term welding quality.

- The fixture can rotate automatically, and after the A-side welding is completed, it is automatically transferred to the flipping mechanism to flip the fixture to the B-side, and the other end is welded to the B-side.

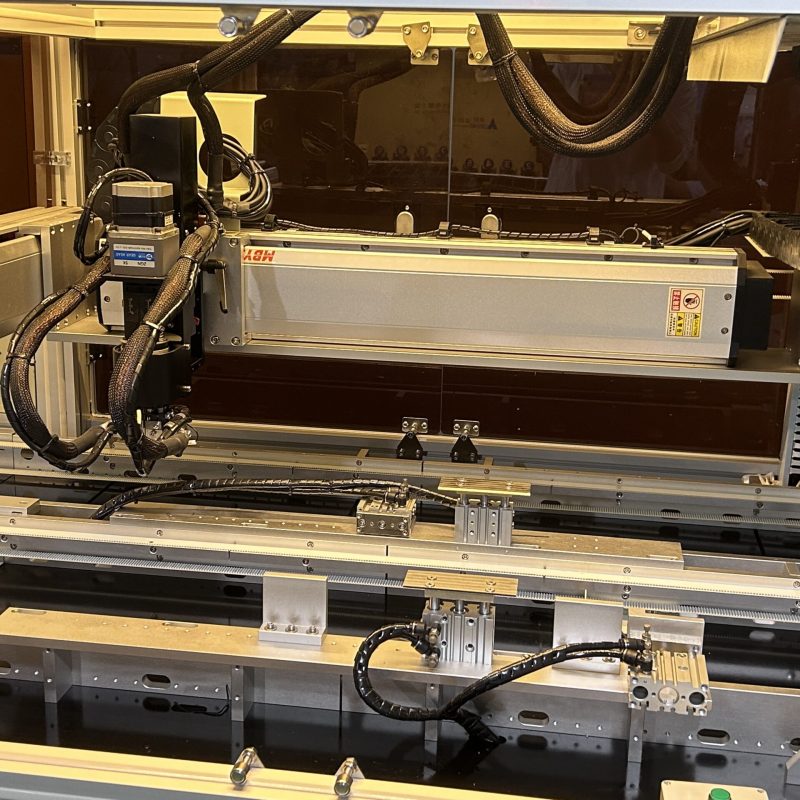

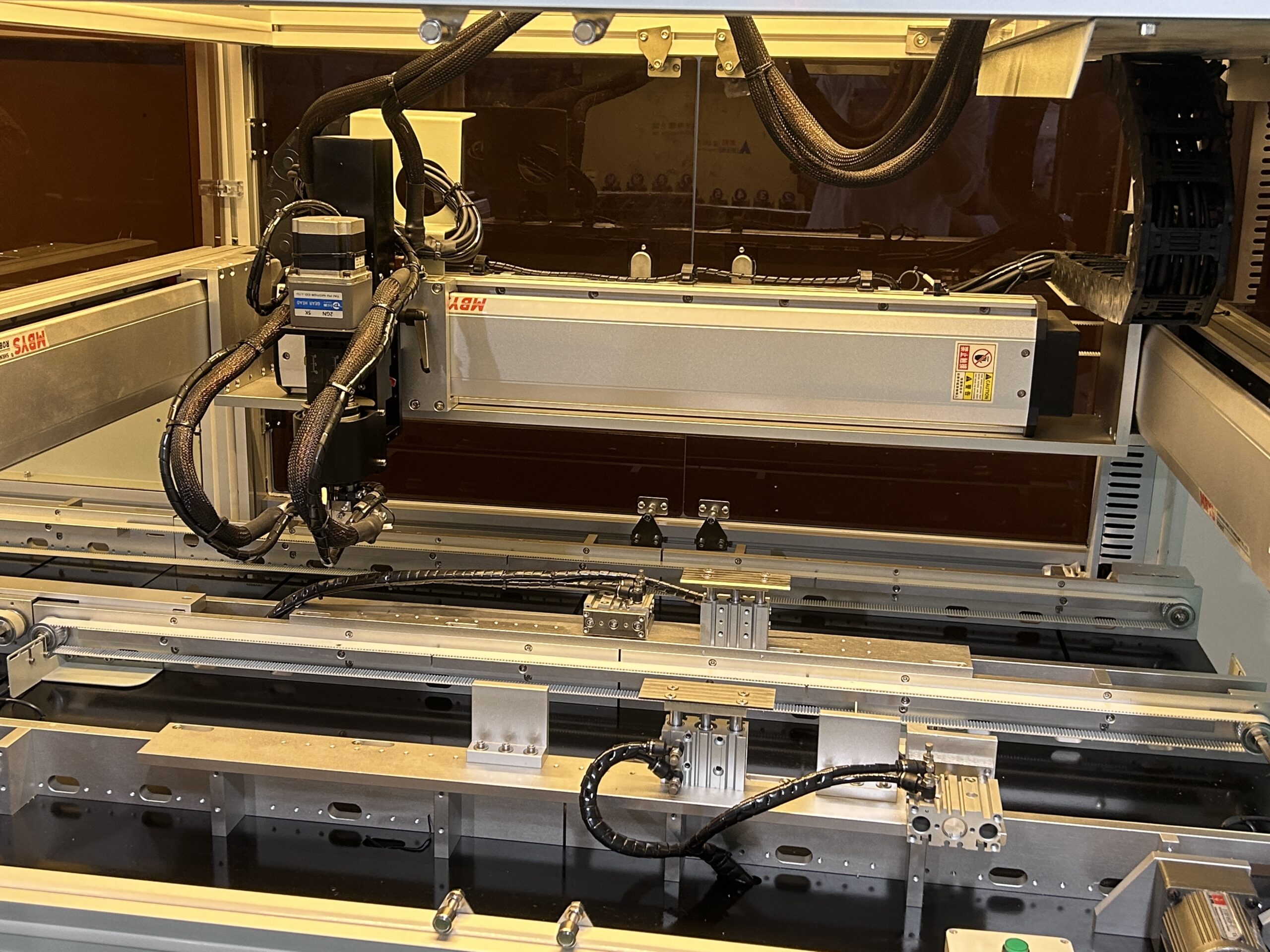

- Equipped with dual welding heads, welding does not stop, with a high degree of automation and no need for manual operation throughout the entire process, effectively improving welding efficiency.

- The left and right welding heads have independent operating systems, which can set different welding paths and angles for welding.

- 135°electric precision rotating welding head, suitable for various shaped nickel sheets, with anti sticking needle function.

- Explosion welding and weak welding equipment automatically alarm, manual adjustment of automatic area welding repair, single point welding repair.

- Using Taiwan's silver wire rod guide module, it has high precision, low noise, smooth sliding, and durability.

- Belt transmission, left and right through design, can be directly connected to the back-end production line after welding is completed.

Technical Specs details presentation

| Main technical specifications | |

| Equipment capacity | 30-40PPM |

| Compatible Battery | 18650–33140 |

| Compatible Modules | <600*400MM(Customizable) |

| Welding thickness | 0.02-0.3MM |

| Repositioning accuracy | ±0.01 |

| Welding head rotation angle | 0~135° |

| Welding power source | Transistor/Multi pulse |

| Weld pressure | 5KG/F(Adjustable) |

| Cooling method | Water circulation cooling |

| Driving method | pneumatic |

| Size weight | 1400*1000*1680MM 560KG |

| Power | 220V 50/60HZ |

Single-Sided Dual-Welding Head

After completing welding on Side A, the flipping mechanism rotates the battery to Side B, where it flows to the next station for welding. Single-sided welding enhances quality, while the flipping mechanism paired with dual welding heads boosts production efficiency.

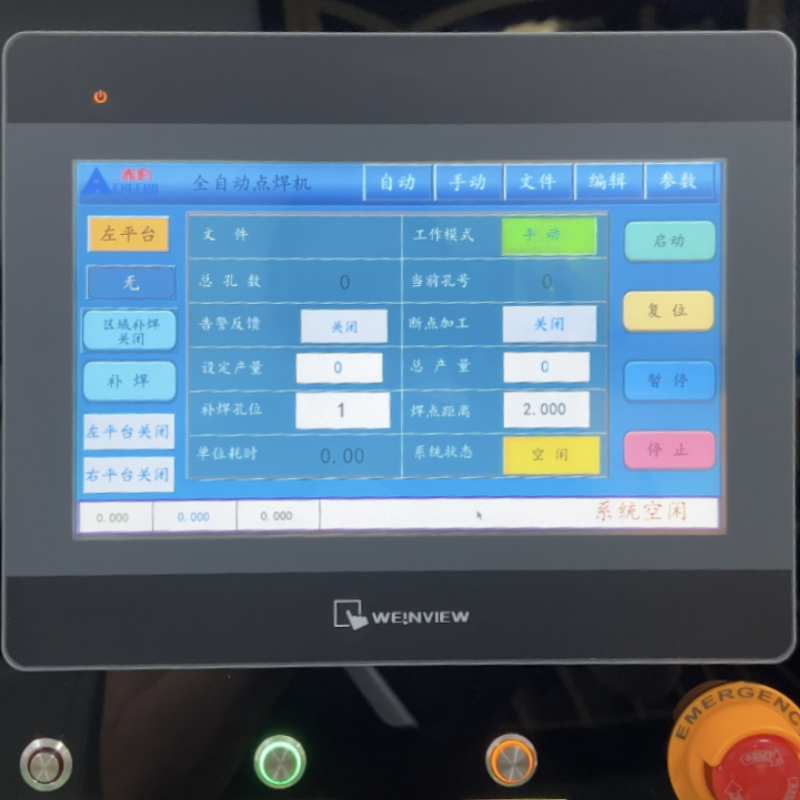

Intelligent Programming Operation

Supports CAD path import, manual programming, and computer programming. Stores up to 190 welding recipes for flexible and efficient operation.

Upper silver wire rod guide rail module

Using Taiwan's silver wire rod guide module, it has high precision, low noise, smooth sliding, and durability.

Water-Cooled Circulation System

The welding head features an integrated water-cooling system, preventing overheating during extended operation. This ensures consistent welding results and extends the life of the welding needle. Equipped with a needle grinding reminder function.

Reviews

There are no reviews yet.