Description

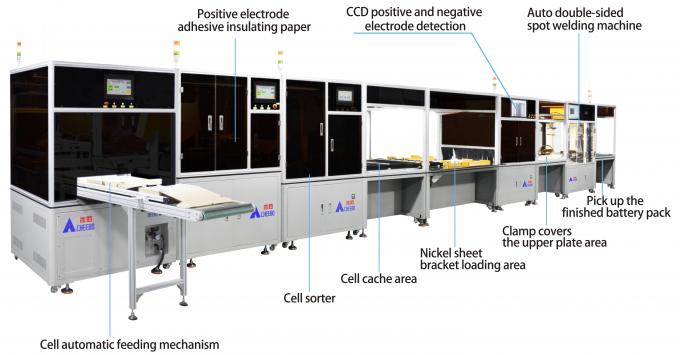

Automatic Lithium Battery Production Line

,

Multi-Functional Lithium Battery Production Line

,

18650 Lithium Battery Production Line

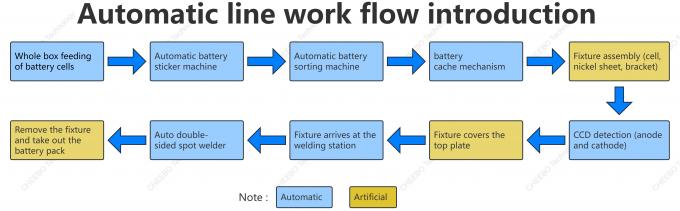

Efficient lithium battery cylindrical pack fully automatic multifunctional 18650 battery module assembly wiring

1. Applicable batteries: The entire production line is suitable for cylindrical steel-cased batteries including 18650, 21650, 21700, 26650, 32650, and 32700 (the CCD and double-sided eight-axis automatic spot welding machine can also be used for 33140 resistance welding batteries).

2. The battery is fed in a whole box, saving labor and time.

3. The production line is designed as a whole, with the battery charging mechanism located at the front, making it simple to operate and visually appealing.

4. The discharge of sorted cells is directly sent to the operation station for cell installation and release, saving labor and time.

5. The fusion design of the human-machine tooling bench and the line body facilitates operation.

6. CCD automatically senses the incoming and outgoing of materials, automatically intervenes during normal operation, and requires manual handling when product abnormalities are detected.

7. The eight-axis double-sided automatic spot welding machine can spot weld slotted batteries in different directions.

8. The spot welding machine is placed at the head of the production line's conveyor belt, connecting the heads of the production line and integrating the entire line.

9. The smooth fixture reflux mechanism design is easy to operate and use, without taking up extra space.

10. Customized production can be arranged according to specific needs.

| Compatible cell models | 18650/21700/32700/26650/32650, etc Cylindrical cell |

| Dimensions | Dimensions |

| Line color | Ivory white(Customizable) |

| Total power | 220V 50/60Hz 6KW |

| Use air pressure | 0.5-0.8Mpa |

| Production efficiency | 3000PCS/H(Automatic part) |

| CCD lens pixel | 2000W |

| CCD detection field | 380*500MM(Max) |

| Spot welder welding stroke | 500*360MM(Max) |

| Cell sorting channels | 6+1 |

| Nickel sheet welding thickness | 0.02-0.3MM |

| Number of stickers (Each time) | 4PCS(Depends on cell type) |

| User interface | Touch screen |

| Manpower required | 3-5 people |

Power tool battery pack, energy storage battery pack, electric vehicle battery pack (including but not limited to)

Q: I don't know which one is right for me?

A: Please tell us the following information

1) What type of cell do you want to assemble? What is its model number? 2) Capacity and volume of battery pack? 3) How many battery packs should be produced per day

Q: How do I install and run the machine?

A: Our technicians had installed the machine before shipment. For the installation of some widgets, we will send out detailed

training videos and user manuals randomly. 95% of customers can teach themselves.

Q: What's your minimum order quantity?

A: We don't have a minimum order quantity. Whether it is an order of 1 or 100, we will wholeheartedly support you.

Q: How does your factory do in terms of quality control?

A: Quality comes first. More than 20 tests will be performed on each unit. After all the tests are passed, our QC will test the

welding performance.

Q : When the machine can't work well, what should I do?

and then give you solution way very soon.

training until you can use machine freely. During installation, we will have our professional engineer to your country to train

your stuff to use it.

Reviews

There are no reviews yet.