Description

Equipment Description:

An automated equipment that integrates high efficiency, high safety and high stability.

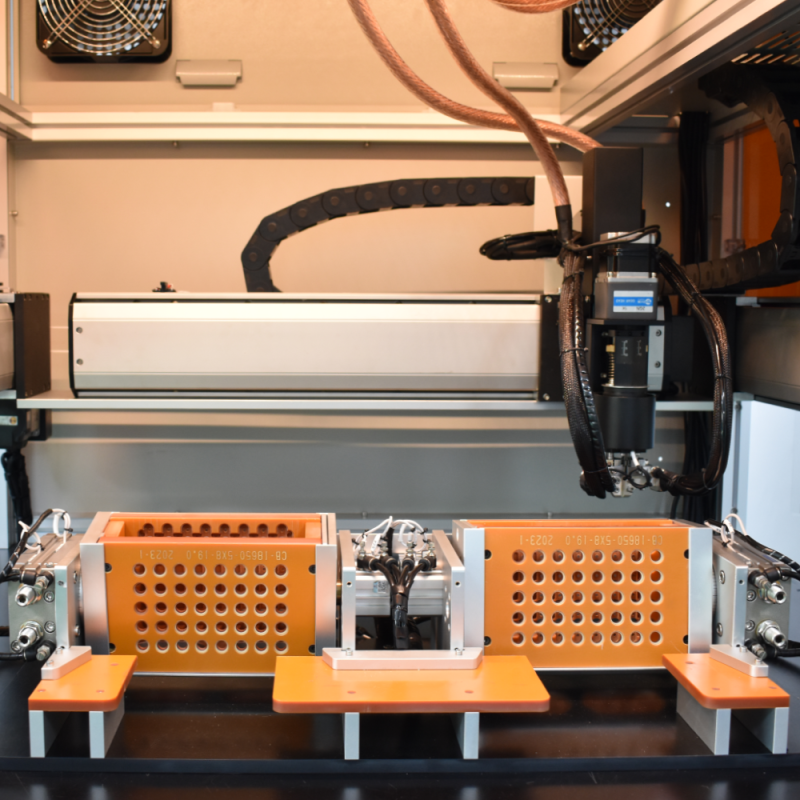

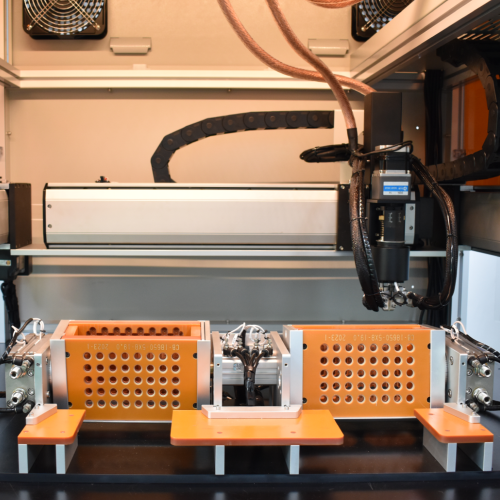

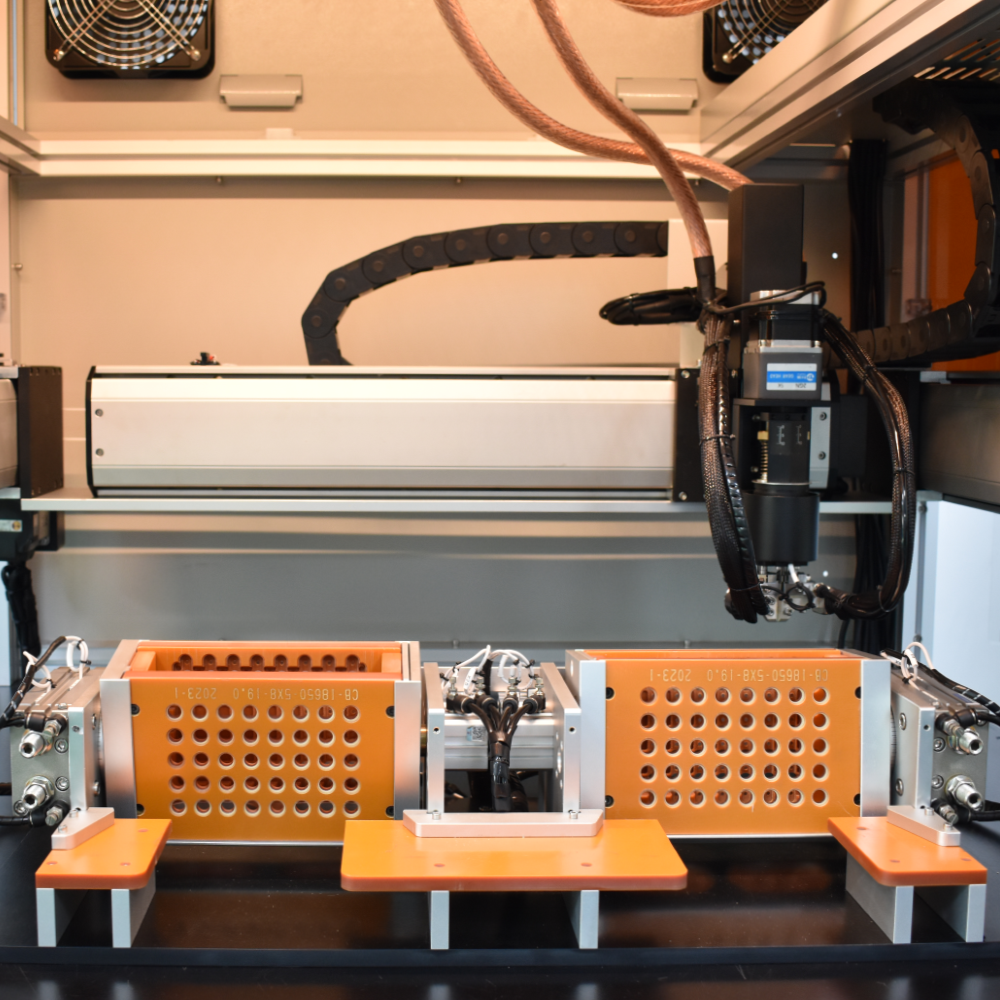

●High efficiency: With two welding stations and an integrated rotating mechanism, the efficiency doubles, and the production cycle is seamlessly connected, enabling continuous cyclic production.

●High safety: Through the physical layout of the rotating mechanism, the welding area is naturally separated from the loading and unloading area. The operation is safe, with human-machine isolation, avoiding the risks of crush injuries and arc burns.

●High precision: Moving the workpiece under the fixed welding gun for welding, the positioning of the rotating table is precise, ensuring that each workpiece reaches the position under the welding gun almost identically.

- The fixture has an automatic rotating mechanism, which can automatically flip the A-side to B-side welding after welding is completed, without the need to manually flip the fixture.

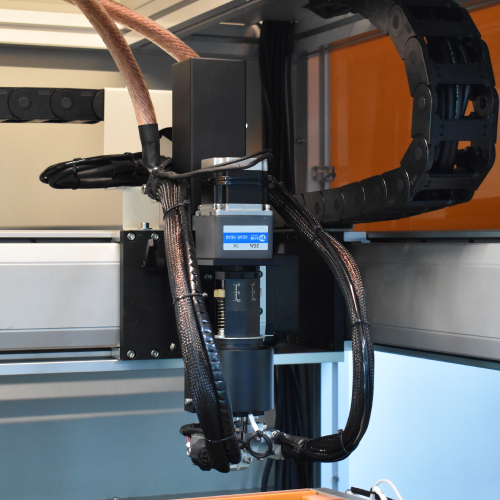

- 135 electric precision rotating welding head, suitable for various shaped nickel sheets, with anti sticking needle function.

- Install grating protection on both sides to ensure safe operation of the equipment.

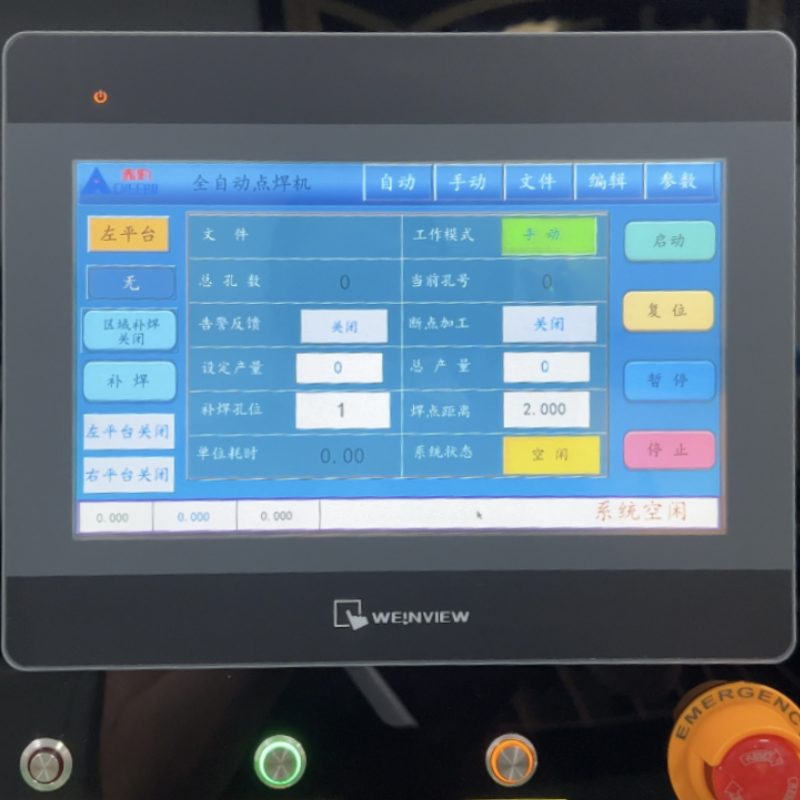

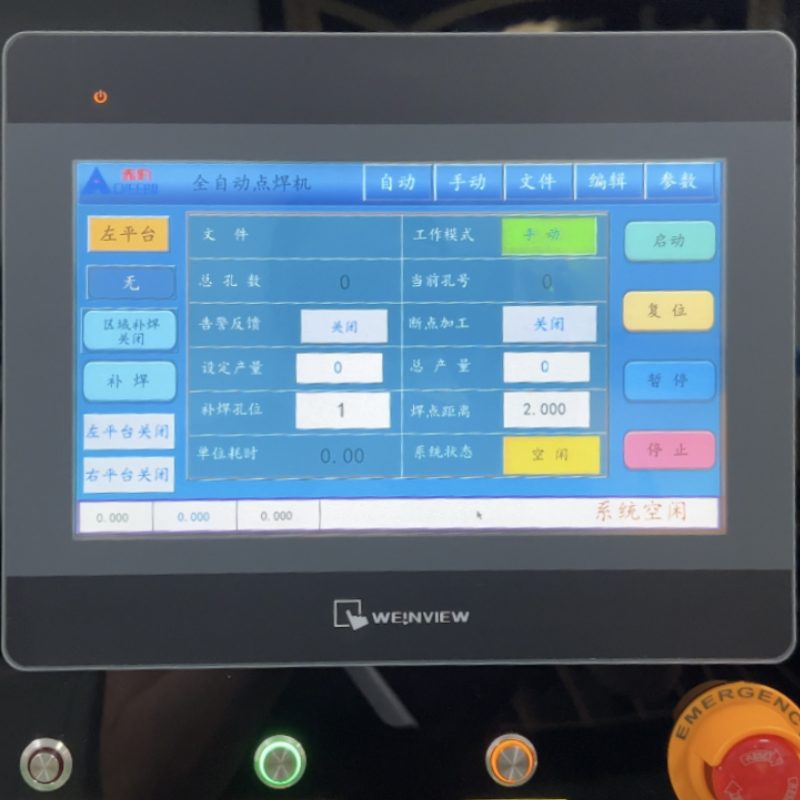

- The virtual welding equipment automatically alarms, manually adjusts the automatic area for welding repair, and performs single point welding repair.

- High definition LCD touch screen, interactive human-machine interface with simple and convenient operation.

- Manual programming, CAD mapping, importing spot welding paths, easy to learn and quickly implement programming.

- Independently develop various automated intelligent systems to facilitate device operation and help improve production efficiency.

- Equipped with energy switching function, production counting function, welding needle compensation function, manual debugging function, etc.

- Aluminum alloy structure, electrostatic powder coating process, scratch resistant, rust proof, anti-static.

- Aluminum alloy skeleton, imported acrylic protective plate, beautiful and elegant, strong sense of technology, visual operation improves production safety factor.

Technical Specs details presentation

| Main technical specifications | |

| Equipment capacity | 30-40PPM |

| Compatible Battery | 18650–33140 |

| Compatible Modules | <600*400MM(Customizable) |

| Welding thickness | 0.02-0.3MM |

| Repositioning accuracy | ±0.01 |

| Welding head rotation angle | 0~135° |

| Welding power source | Transistor/Multi pulse |

| Weld pressure | 5KG/F(Adjustable) |

| Cooling method | Water circulation cooling |

| Driving method | pneumatic |

| Size weight | 1400*1000*1680MM 380KG |

| Power | 220V 50/60HZ |

Dual-station design

The fixture has an automatic rotating mechanism, which can automatically flip the A-side to B-side welding after welding is completed, without the need to manually flip the fixture.

Rotating welding head

135 electric precision rotating welding head, suitable for various shaped nickel sheets, with anti sticking needle function.

High-Precision Rotating Welding Head

Our independently developed 135° rotating welding head is ideal for welding irregular nickel plates. Pure nickel construction prevents needle sticking. Welding pressure is precisely adjustable via a buffer spring pressure adjustment mechanism, effectively minimizing damage to battery cells.

Intelligent Programming Operation

Supports CAD path import, manual programming, and computer programming. Stores up to 190 welding recipes for flexible and efficient operation.

Reviews

There are no reviews yet.