Description

Battery Pack Automated Visual Inspection Equipment

,

Polarity Detection Automated Visual Inspection Equipment

Battery Pack Positive And Negative Polarity Automated Visual Inspection Equipment

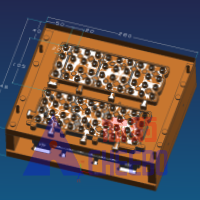

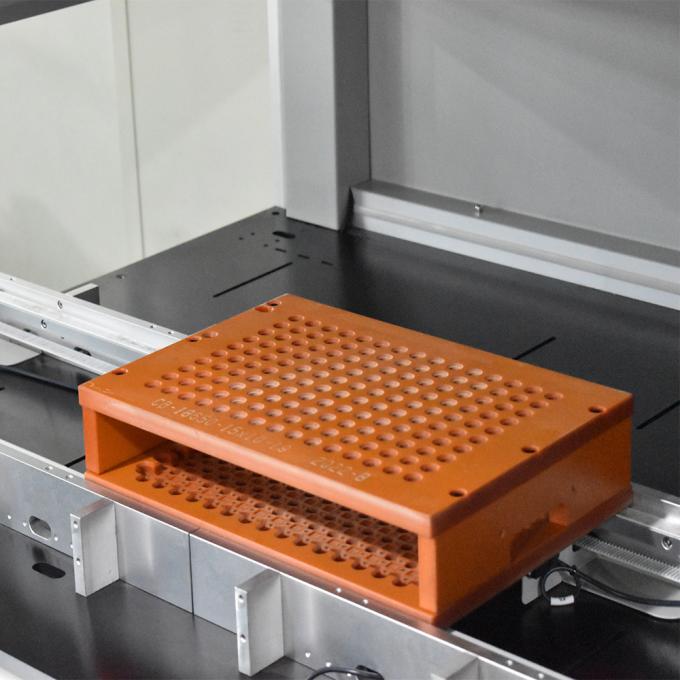

● A multi-purpose vision inspection system for CCD vision inspection equipment based on CCD industrial camera using machine vision technology.

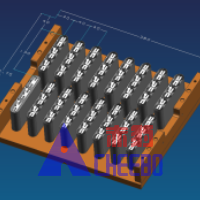

● It is suitable for polarity grid measurement of many kinds of cells, saves labor cost, and can carry out high repetitive work.

● CCD visual inspection can work stably for a long time, good reliability, high detection accuracy and manual debugging function. It can fine-tune and save the parameters of the monitoring area for each detection, and can also be adjusted for the use of the overall offset function.

● With counting function, you can count the number of OK/G.

● It has the function of automatic detection of fixtures.

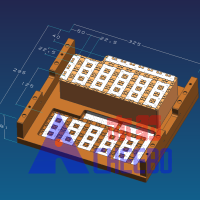

● Support for multi-lock plate comparison, up to 100 sets of templates.

● The use of light height adjustable design, in a variety of lighting environment can be used.

| Testing range | 250*400MM | Lens pixel | 500W pixel HD lens |

| Detection efficiency | 3-5s/PCS | Accuracy | 99.99% |

| Transmission mode | Belt transmission | Weight | 150KG |

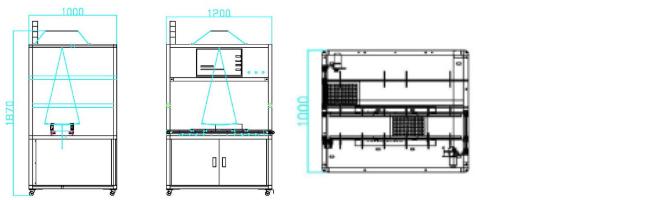

| Display mode | Graphical display | Dimensions | 1200*1000*1870MM |

| Device system algorithm | CHEEBO CCD special system algorithm | Application scenario | Polarity detection of various cells |

| Detection algorithm | Positioning, measurement, flatness, contrast, presence or absence | Reminder | Sound and light alarm, wrong position color change |

1. Energy storage battery pack 2. Electric bicycle battery pack 3. Power tool battery pack

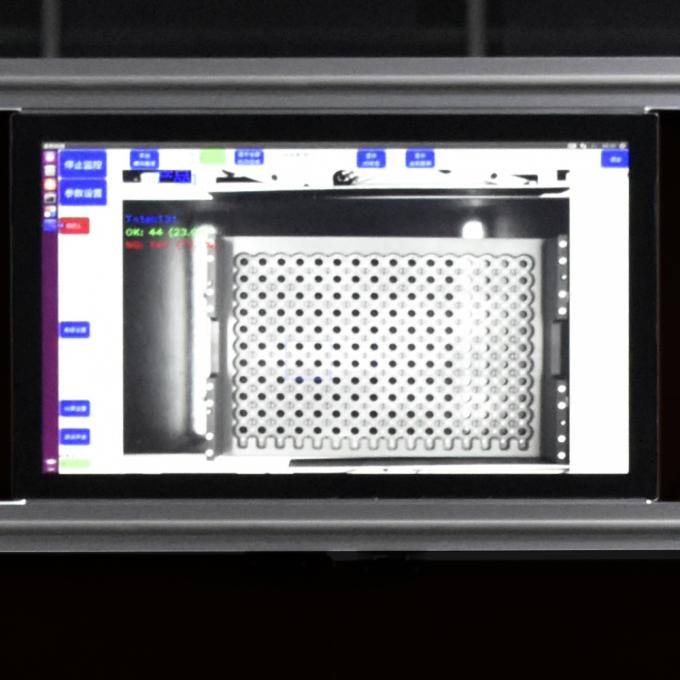

1. 19 "HD touch screen

Clear display, mouse and keyboard configuration, easy to operate, simple and fast, only industrial control system, can store all the test results, convenient verification of data.

2. Large detection range

Support a variety of cell models, detection range: 250*400mm. Can be customized according to requirements.

1. Customers send inquiries and inquiries

2. Recommend products according to customer needs

3. Video communication to confirm final requirements

4. Both parties shall deliver the confirmation of technical specifications

5. Both parties sign the contract

6. Place orders and arrange production in the workshop

7. Arrange delivery

After sale:

1. Confirm whether customers need on-site service or video communication guidance for debugging equipment.

2. If there is any problem with the equipment, video communication will be adopted to solve the problem first. Door-to-door service can be provided if there is no solution.

Looking forward to your consultation, we will provide you with the best quality service throughout the process!!!

Reviews

There are no reviews yet.