Description

Detail Information

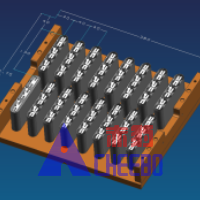

● The fully automatic lithium battery spot welding machine is independently developed with an electric precision rotating welding head that can rotate 135 ° for welding, suitable for various irregular nickel sheets and has anti sticking needle effect.

● The CBMN8-5036 double-sided lithium battery spot welding machine can be operated independently on the left and right platforms, and the welding path can be set independently according to different welding needs.

● Automatic alarm for explosive welding and false welding equipment, manual adjustment for automatic zone repair welding, single point repair welding.

● Adopting Taiwan’s silver screw guide rail module, high-precision, low noise, smooth sliding, and durable.

● Adopting a through design structure (both forward and backward), it can be connected to the production line through and used. After welding is completed, it can be taken out on the production line side.

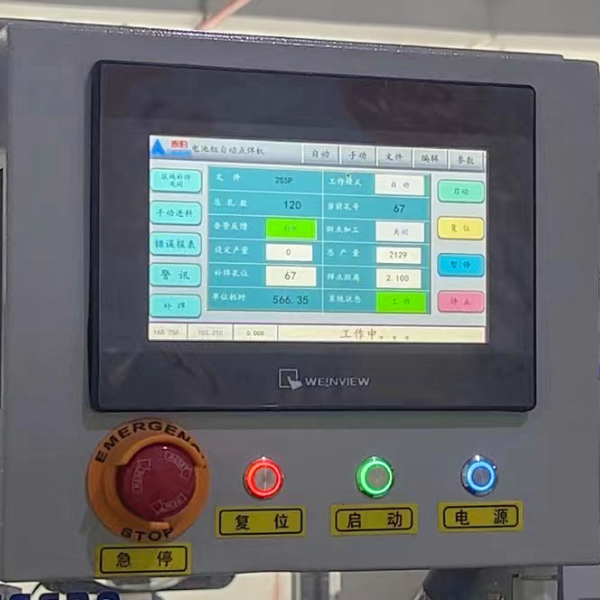

● The lithium ion battery assembly equipment adopts a high-definition LCD touch screen, and the interactive human-machine interface is simple and convenient to operate. Manual programming, CAD mapping, import spot welding paths, and quickly achieve programming. Easy to learn, it can be set up by ordinary workers.

● Energy switching function, which can store 4 sets of energy modes, and automatically switch different welding energies for different materials.

● Production counting function, set production quantity, and automatically shut down after completing production.

● Welding needle compensation function, setting the number of welding needles, and automatically reminding for welding needle maintenance after reaching the number of times.

● The manual debugging function allows for fine-tuning of the welding head and saving of spot welding parameters for each point (making it easy to modify the coordinates of the welding points), and can also be adjusted using the one click calibration function.

● Aluminum alloy skeleton, imported acrylic protective plate, beautiful and elegant with strong sense of technology, visual operation to improve production safety factor.

| Production efficiency | 3600PCS/H | Welding head rotation | Yes |

| Welding thickness | 0.02-0.3MM | Type of cooling | Forced water circulation cooling |

| Welding source | Transistor/multipulse (Optional) | Mode of motion | Automatic continuity |

| XY shaft welding accuracy | 0.1MM | Welding pressure | 5KG/F |

| Electrode material | Copper alumina | Machine Dimensions | 1400*1000*1680MM |

| XY shaft welding stroke | 360MM*500MM | Machine Weight | 330KG |

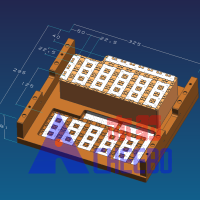

| Power source specification | Single-phase 220V50/60HZ | Application scenarios | Cylindrical battery welding |

1. Hd touch screen

Real-time display of welding data, welding hole location. System parameter setting is simple and easy to learn.

Support manual programming, CAD mapping, import solder joint path to achieve fast programming.

2. Electric rotating welding head

The welding head can be welded by 135° rotation, suitable for special-shaped nickel sheet, and also has the function of anti-sticking needle.

The built-in pressure sensor can monitor and control the instantaneous output pressure of the welding head.

3. Cooling system:

Water circulation heat dissipation, instantaneous large current welding, welding head always maintain constant temperature, effectively reduce the loss of welding needle, improve the welding effect.

1. Energy storage battery pack 2. Electric bicycle battery pack 3. Power tool battery pack

Service process

Pre-sale:

1. Customers send inquiries and inquiries

2. Recommend products according to customer needs

3. Video communication to confirm final requirements

4. Both parties shall deliver the confirmation of technical specifications

5. Both parties sign the contract

6. Place orders and arrange production in the workshop

7. Arrange delivery

After sale:

1. Confirm whether customers need on-site service or video communication guidance for debugging equipment.

2. If there is any problem with the equipment, video communication will be adopted to solve the problem first. Door-to-door service can be provided if there is no solution.

Looking forward to your consultation, we will provide you with the best quality service throughout the process!!!

Reviews

There are no reviews yet.