Description

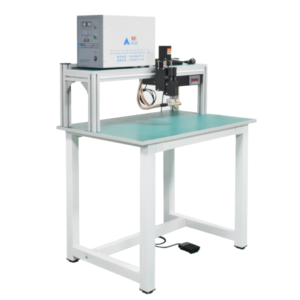

Equipment Description:

A high-precision and highly automated lithium battery welding equipment specially designed for the production of high-end battery packs.

● High flexibility: With high motion flexibility, it can easily handle complex and multi-angle welding requirements, with almost no blind spots.

●High efficiency: When it is necessary to change the production model or workpiece, simply call the corresponding program, and the equipment can adjust its posture and trajectory, suitable for mixed production modes with multiple varieties.

●High quality: Servo motors and high-precision reducers ensure that the position of each weld point is accurate without error.

- Electric precision rotating welding head, suitable for various shaped nickel sheets, with anti sticking needle function.

- The left and right platforms can be operated independently, and different welding paths can be set for the left and right welding heads.

- The fixture transmission mechanism automatically senses that the fixture is in place, and then the conveyor belt transports the fixture to the welding station.

- Water circulation cooling system to prevent welding head from heating up and ensure welding quality.

- Automatic alarm for explosion welding and weak welding, manual adjustment for automatic area welding repair, single point welding station.

- Manual programming, CAD mapping, importing spot welding paths, and quickly implementing programming. Easy to learn, ordinary workers can set it up.

- independently developed various automated intelligent systems, including energy switching function, production operation and help improve production efficiency.

- Adopting a through type design structure(capable of both forward and backward movement),it can be connected to the production line for continuous use.After welding, it can be removed from the assembly line side.

- Aluminum alloy skeleton, imported acrylic protective plate, beautiful and elegant, strong sense of technology comprehensive visual operation to improve production safety factor.

Technical Specs details presentation

| Main technical specifications | |

| Equipment capacity | 60-70PPM |

| Compatible Battery | 1865-0-33140 |

| Compatible Modules | <500*360MM(Customizable) |

| Welding thickness | 0.02-0.3MM |

| Repositioning accuracy | ±0.01 |

| Welding head rotation angle | 0~135° |

| Welding power source | Transistor/Multi pulse |

| Weld pressure | 5KG/F(Adjustable) |

| Cooling method | Water circulation cooling |

| Driving method | pneumatic |

| Size weight | 1400*1000*1680MM 380KG |

| Power | 220V 50/60HZ |

Rotating welding head

Our independently developed 135° rotating welding head is ideal for welding irregular nickel plates. Pure nickel construction prevents needle sticking. Welding pressure is precisely adjustable via a buffer spring pressure adjustment mechanism, effectively minimizing damage to battery cells.

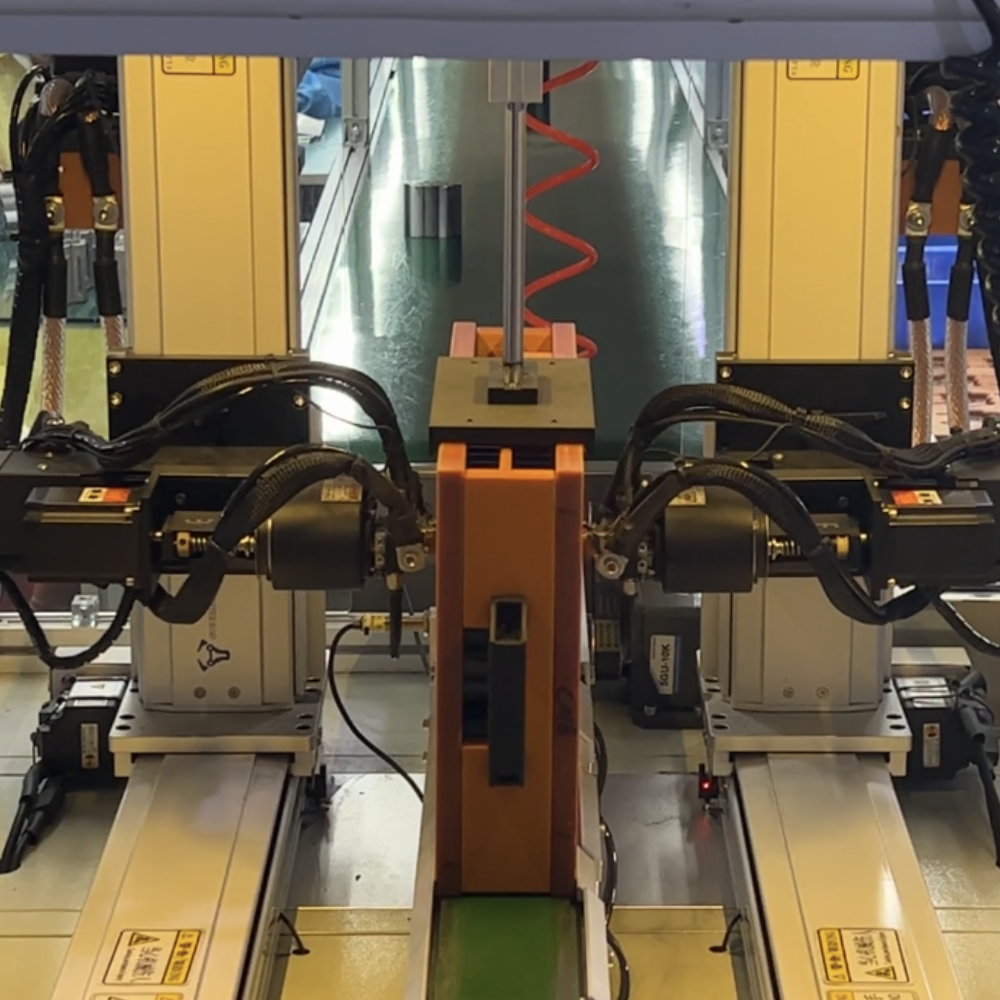

Dual-platform independent control

The left and right platforms can simultaneously perform spot welding at different positions and angles without interference, offering high flexibility and suitability for complex welding paths.

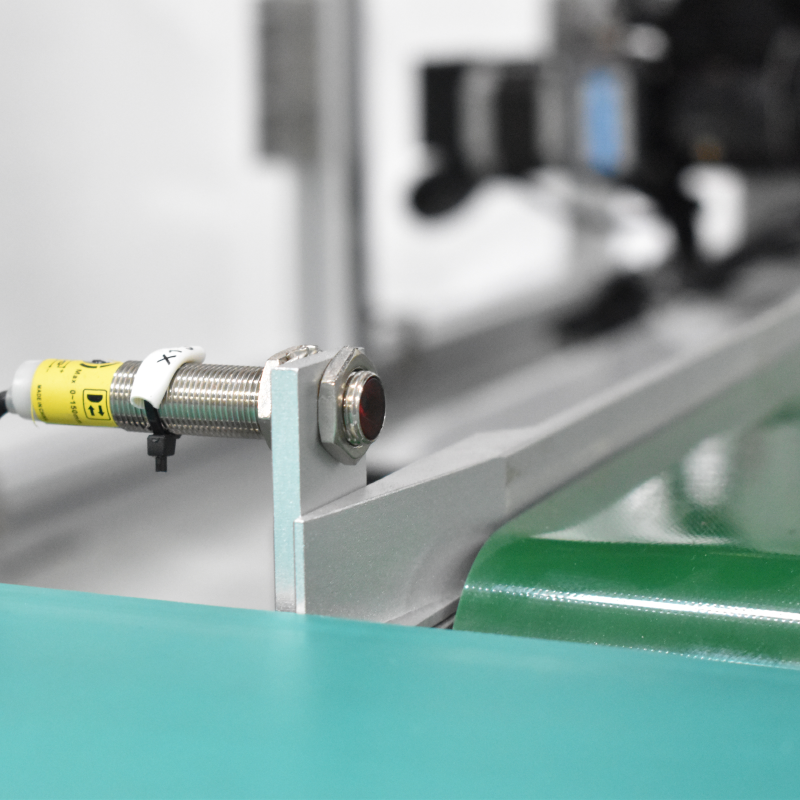

Automatic sensor

Continuous design, belt automatic conveying, fixture automatic sensing for welding. The entire process is fully automatic, with the rear end capable of automatically flowing to the assembly line.

Water-cooling circulation device

The welding head features an integrated water-cooling system, preventing overheating during extended operation. This ensures consistent welding results and extends the life of the welding needle. Equipped with a needle grinding reminder function.

Reviews

There are no reviews yet.