Description

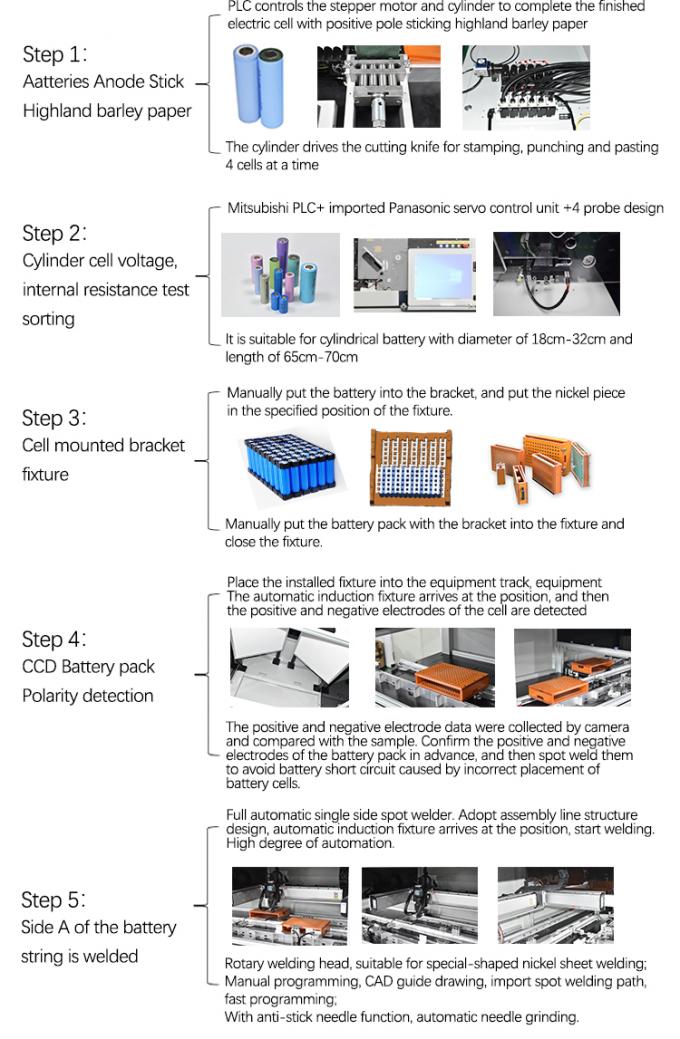

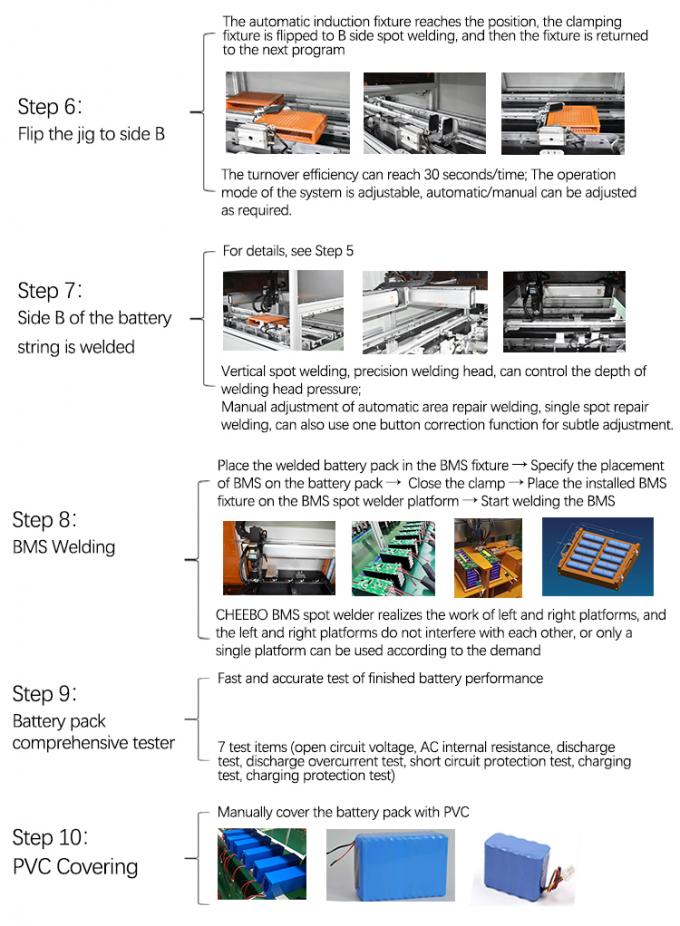

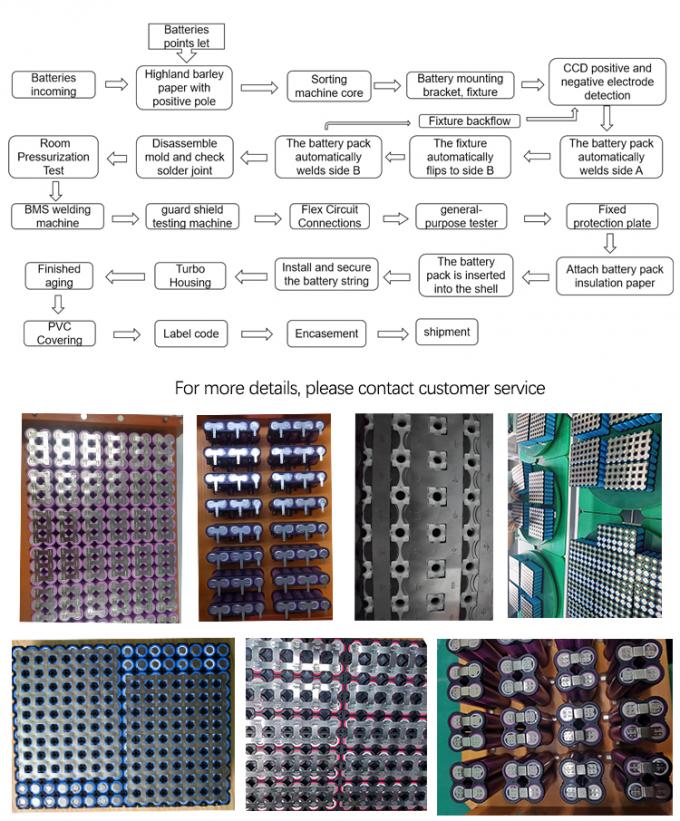

18650 lithium battery assembly line

,

battery pack production line

,

lithium battery pack assembly machine

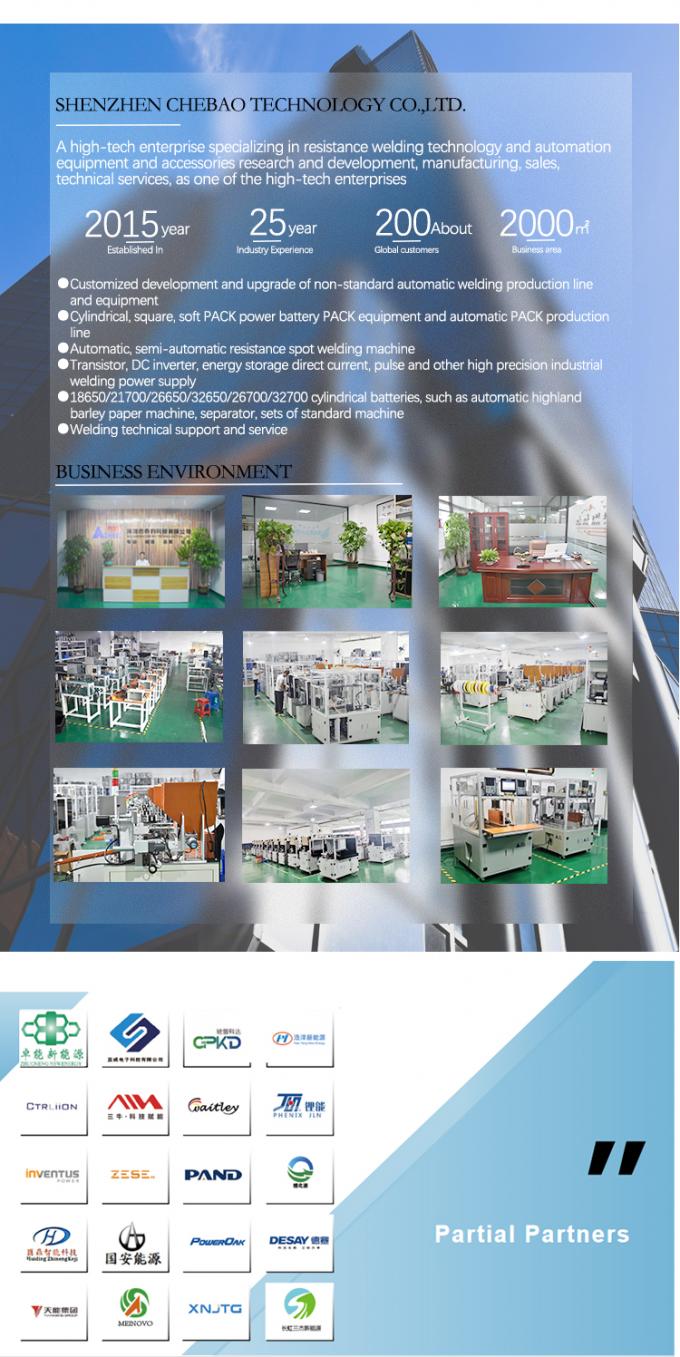

- Modern automation technology with multi-axis control

- Precision transmission and motor control mechanism

- Suitable for 18650, 21700, 26650, 32700 cylindrical cell combinations

- Ideal for NB/PowerTool/GardeningTool/HighPower applications

- Energy storage power station and electric vehicle battery production

- Premium materials and quality assurance

- All-copper transformers and imported electronic components

- High-power industrial grade performance

- Supports 0.05mm~0.2mm nickel sheet welding

- 24-hour continuous operation capability

- Low failure rate with maintenance support

Reviews

There are no reviews yet.