Description

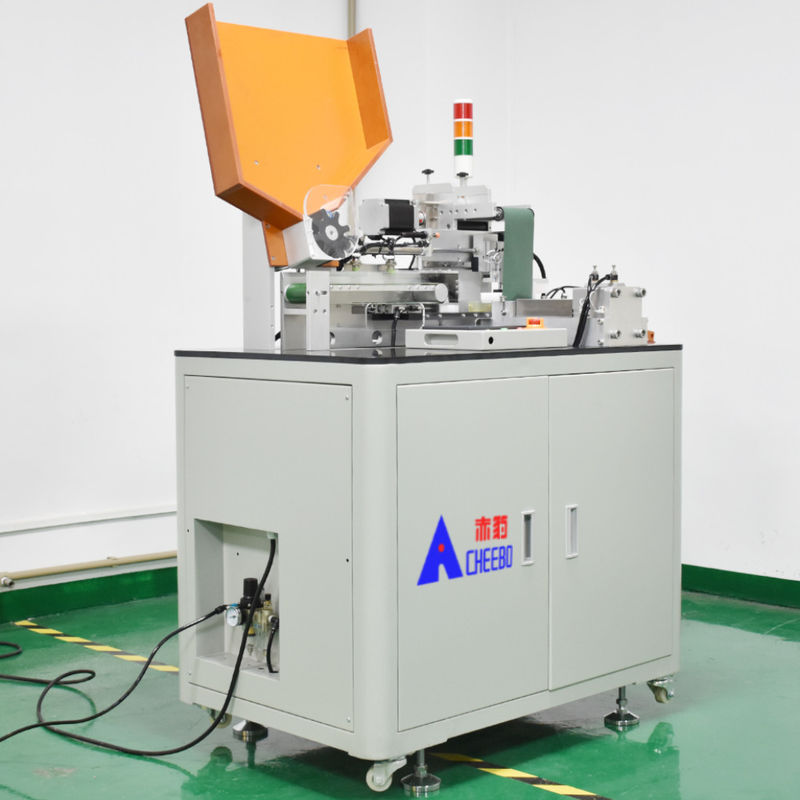

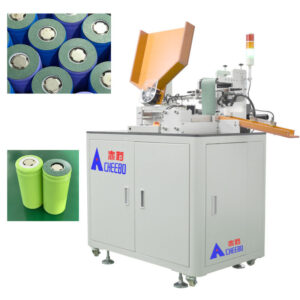

Battery Labeling Machine 21650

,

Sticker Type Battery Labeling Machine

,

Vertical Labeling Machine 21650

21650 Cylindrical Battery Cell Vertical Fully Automatic Lithium Battery Sticker Machine

● This sticker machine is controlled by a PLC to complete the function of applying highland barley insulation paper to the positive electrode of 18650/21700/21650 finished battery cells, such as stepper motors and cylinders.

● Approximately 4000 finished cylindrical cells can be completed per hour.

● Adopting a 7-inch high-definition touch screen, real-time monitoring of machine operation status.

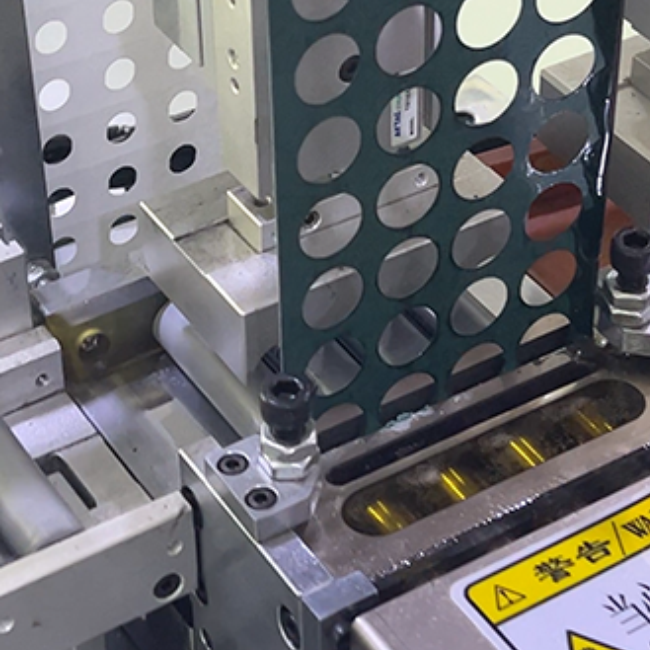

● Using a cylinder driven cutting knife for stamping, four battery cells are punched at once, and the slices are made of high-speed steel material, with high wear resistance, good product quality, and high production efficiency.

● Sticker and stamping are stable, with high consistency in placement and low defect rate.

● Fault information reminder function, fault sound and light alarm, can quickly diagnose faults.

● With the function of clearing tailings, it can clear tailings with one click.

● Compatible materials: highland barley paper, express paper, Oblaat, RET protective sticker, etc.

● The mechanical structure design is simple and generous, and the system performance is stable.

| Production efficiency | 60-70PPM | Air source specification | 1/CFM |

| Applicable battery specifications | 18650/21700/21650 | Pass rate | ≥95% |

| Sticker efficiency | ≥60PPM | Transmission mode | Mechanical hand |

| Compatible material | Highland barley paper, fast bus paper, glutinous rice paper, RET protective stickers, etc | Maximum impact speed | 99.99% |

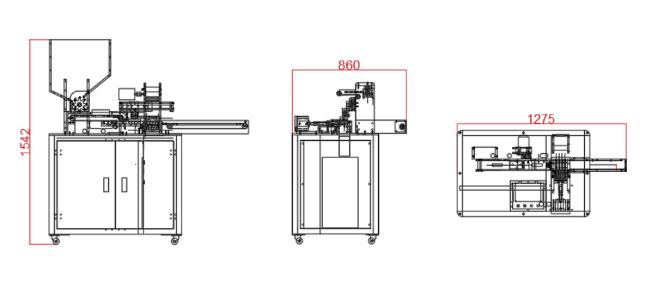

| Work method | Stepper motor + pneumatic | Machine Dimensions | 1275*860*1524MM |

| structural material | aluminium alloy | Machine Weight | 150KG |

| Power source specification | Single-phase 220V50/60HZ | Application scenarios | Cylindrical cell sticker |

- Wear highland barley paper steps

- Adjust the press cutter

- Adjustable center position

- Loading step demonstration

- On-line debugging

- Replace stamping tool debugging

Manually load the battery into the hopper – the wave wheel rotates out of the battery – the belt moves the battery – the cylinder launches the battery

team – the battery positioning and pressing – the stepping battery drives the whole roll of highland barley paper to move – the cylinder paste

highland barley paper – waste recycling – the finished battery to the feeding tank – the human tooling box

(Operating parameters can be freely set according to actual requirements)

1.Hd touch screen

7 inch HD touch screen, real-time display of machine running status. With fault alarm device, quickly determine the fault point, after adjustment can continue production.

2.High speed steel cutter

The stamping die is non-adhesive and firmly pasted. The paste position is consistent and does not affect the subsequent welding procedure. Paste 4 cells at one time, high production efficiency

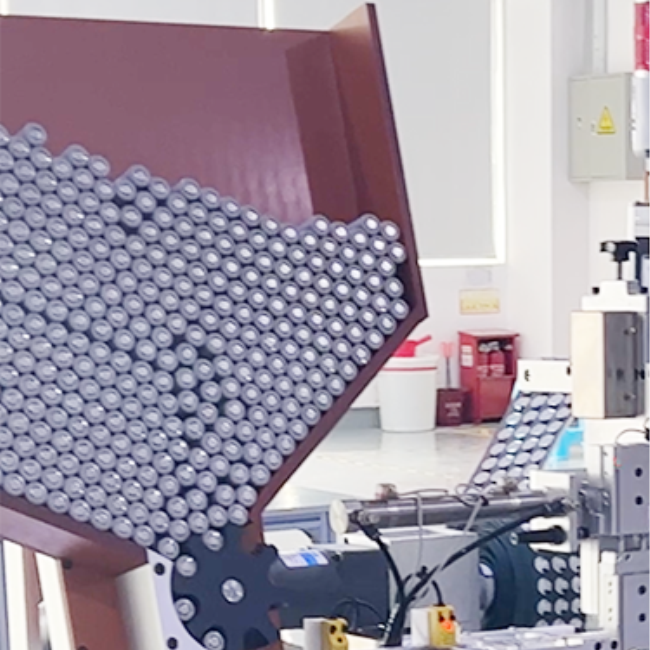

3.Large hopper

Large feeding hopper, slope type hopper, suitable for the whole box feeding, feeding convenient. One-time 300PCS18650 battery cell.

Reviews

There are no reviews yet.