Description

Automatic Lithium Cell Testing Machine

,

Cylindrical Lithium Cell Testing Machine

,

Cylindrical BMS Tester

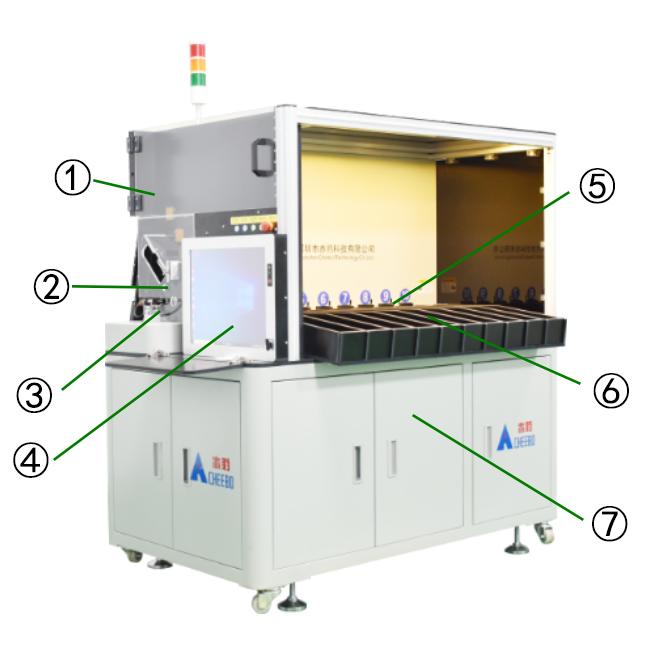

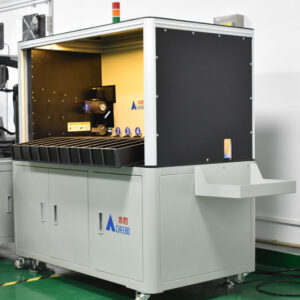

18650/21700 Battery Cell Sorting Machine Cylindrical Cell Universal Type

● Adopts 10+1 steps design, 11 steps in total. 10 slots for good products and 1 independent storage area for defective products at the back end.

● Adopts PLC + upper computer control method. The upper computer records and displays sorting data in real time, and can save and export sorting data.

● Adopts Mitsubishi PLC + imported Panasonic servo control unit + 4 probes design. The mechanical structure design is simple and generous, and the system performance is stable.

● Using 19" all-in-one industrial grade computer, the sorting data is displayed in real time and the human-machine interaction is simple and convenient.

● Failure information reminding function, sound and light alarm of failure, can diagnose failure quickly.

● Aluminium alloy structure, electrostatic powder coating process, scratch-resistant, rust-proof and anti-static.

● CBFXH-10 multi-functional cylindrical battery testing and sorting machine is a kind of automatic sorting equipment which is suitable for voltage and internal resistance testing of various specifications of cylindrical batteries.

● It can be used for 18650/21700/226650/26700/32650/32700 etc.

● The number of finished cylindrical cells sorted per hour is over 4000.

● Simple operation interface with one-key generation function. Only need to input the starting voltage internal resistance and the corresponding interval to complete the parameter setting.

● With manual parameter modification function, each gear can be adjusted by fine-tuning or one-key modification function.

| 1. Battery charging hopper | 2. Battery type wave wheel replacement area |

| 3. 4 Probe head design | 4. Integrated industrial computer touch screen |

| 5. Flexible belt transmission | 6. 10+1 channel |

| 7. Panasonic servo motor |

| Production efficiency | 50-70PPM | Air source specification | 1/CFM |

| Applicable battery specifications | Diameter: 18-32; Length: 65-70 | Transmission mode | belt transmission |

| Sort the gears | 10+1 | Product loss rate | 0 |

| SBM Series | HIOKI3561/HOPE350 | Frame material | Aluminium alloy |

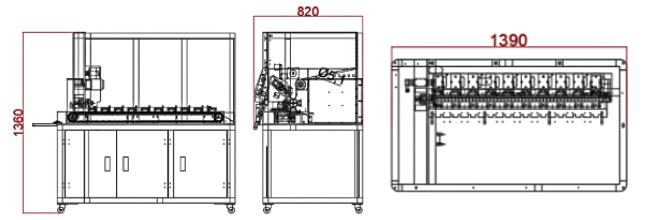

| Voltage accuracy | 0.1% (according to the internal resistance meter) | Machine Dimensions | 1390*820*1360MM |

| Internal resistance accuracy | 0.5%(depending on internal resistance meter) | Machine Weight | 220KG |

| Power source specification | Single-phase 220V50/60HZ | Application scenarios | Cylindrical battery sorting |

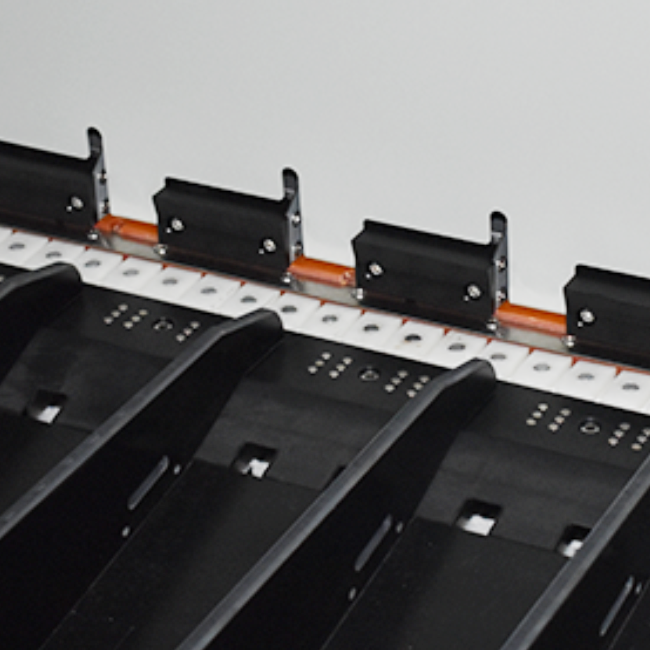

1. Italic design

The ten grades all adopt italic design, open gate, simple and convenient material receiving, saving time and labor, and effectively improving production efficiency.

2. Baffleless design

No baffle design, smooth operation, no lag.The sorting state of the cell at the arrival position is clearly visible.

3. Loading mechanism

Humanized design, easy to fill the whole box. Large hopper, one time can put 400PCS18650 cells.

- Sorting belt is kept clean

- The test needle should be replaced regularly

- The oil-water filter should be drained regularly

- Clean the foreign bodies in the equipment in time

- Only use the machine when the machine is in good condition, the ground protection is good, and all the functions of the machine are normal

- Distance from walls and other facilities ≥1000mm

- Ground requirements: ground level, four foot cup adjustment level

- Height space: ≥2500mm

- Workshop working environment requirements: 10℃ -32 ℃

- Clean welding dust from all parts of the equipment every day

- Check every week that all parts are in good condition

- Monthly check the lubrication status of each moving part timely lubrication (using 0# grease)

- Operation must be in accordance with the specifications of the operation

Reviews

There are no reviews yet.