Description

Lithium Table Top Spot Welding Machine

,

Table Top Spot Welding Machine 30V

,

Lithium Nickel Spot Welder

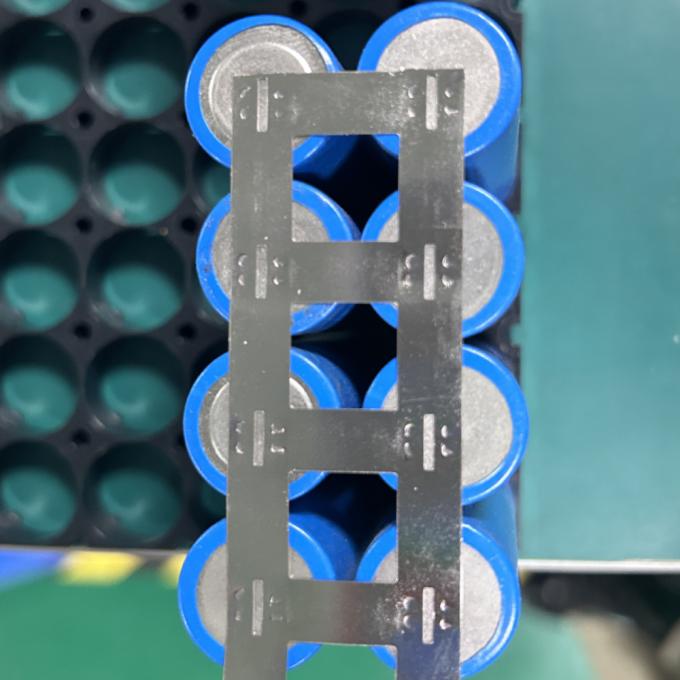

Battery Tab Spot Welding Lithium Battery Pack Nickel Plate Welding

● CHEEBO lithium battery spot welder adopts a self-developed pure electric cylinder free system, with low noise and stable pressure.

● Motor driven, control box precise control, three adjustable modes: single point/semi-automatic/automatic. The welding method of the battery pack can be adjusted according to needs.

● The battery welding machine adopts CHEEBO's self-developed precision welding head, with precise pressure adjustment and control.

● The welding power control adopts a switch switching method, which can achieve small, efficient, and high output welding.

● The power supply of CBLD-5A Battery Sport Welder adopts a transistor welding power supply, which has a fast current rise speed and can achieve high-quality welding in a short period of time.

● Install connection function to effectively improve production efficiency

● Independently developed precision welding machine head, with precise pressure regulation and control.

● Microcomputer technology control, real-time monitoring of welding voltage, current, and resistance waveforms

● 5.7 inch high-definition LED display, device parameter adjustment is convenient and intuitive, and multiple programs can be pre stored.

● There are three welding modes: constant voltage, constant current, and combination of constant voltage and current.

| Welding thickness | 0.02-0.5MM | Welding power supply | Transistor |

| Welding mode | Single side double point horizontal welding | Table top and weld head height | 250 (Maximum pitch adjustable) |

| Supply current | 5000A/8000A/10000A | Welding speed | 200P/M |

| Spot welding method | Bump welding/tip welding | Welding pressure | 5KG/F |

| Maximum voltage | 30V(Adjustable by oneself) | Equipment size | 600*900*1300MM |

| Driving mode | Electric | Machine Weight | 60KG |

| Power source specification | Single-phase 220V50/60HZ | Application scenarios | Battery welding |

1. Electric precision welding head

Motor driven welding, without the need for external solenoid valves and cylinders, with low noise. Horizontal welding structure, double linear guide rail design, left and right pressure can be adjusted separately. Built in pressure sensor for precise control and stable pressure application.

2. Transistor welding power supply

Welding energy output is the most stable power supply, real-time display of welding voltage and current waveform, current rising fast, can achieve high quality welding in a short time.

3. Electric control

No additional air source, low noise, fast welding speed, stable pressure.

-

Welding case

Q: I don't know which one is right for me?

A: Please tell us the following information

1) Battery model and type.

2) Welding material and welding thickness

3) Commercial industry: We have a lot of sales experience and can provide you with advice.

Q: How do I install and run the machine?

A: Our technicians had installed the machine before shipment. For the installation of some widgets, we will send out detailed training videos and user manuals randomly. 95% of customers can teach themselves.

Q: What's your minimum order quantity?

A: We don't have a minimum order quantity. Whether it is an order of 1 or 100, we will wholeheartedly support you.

Q: How does your factory do in terms of quality control?

A: Quality comes first. More than 20 tests will be performed on each unit. After all the tests are passed, our QC will test the welding performance.

Q: How can I do if the machine goes wrong?

A: If you encounter such problems, please contact us as soon as possible. Do not try to repair the machine by yourself or others. We will respond as soon as possible within 24 hours to solve your problem.

Pre-sale:

1. Customers send inquiries and inquiries

2. Recommend products according to customer needs

3. Video communication to confirm final requirements

4. Both parties shall deliver the confirmation of technical specifications

5. Both parties sign the contract

6. Place orders and arrange production in the workshop

7. Arrange delivery

After sale:

1. Confirm whether customers need on-site service or video communication guidance for debugging equipment.

2. If there is any problem with the equipment, video communication will be adopted to solve the problem first. Door-to-door service can be provided if there is no solution.

Looking forward to your consultation, we will provide you with the best quality service throughout the process!!!

Reviews

There are no reviews yet.