Description

Equipment Description:

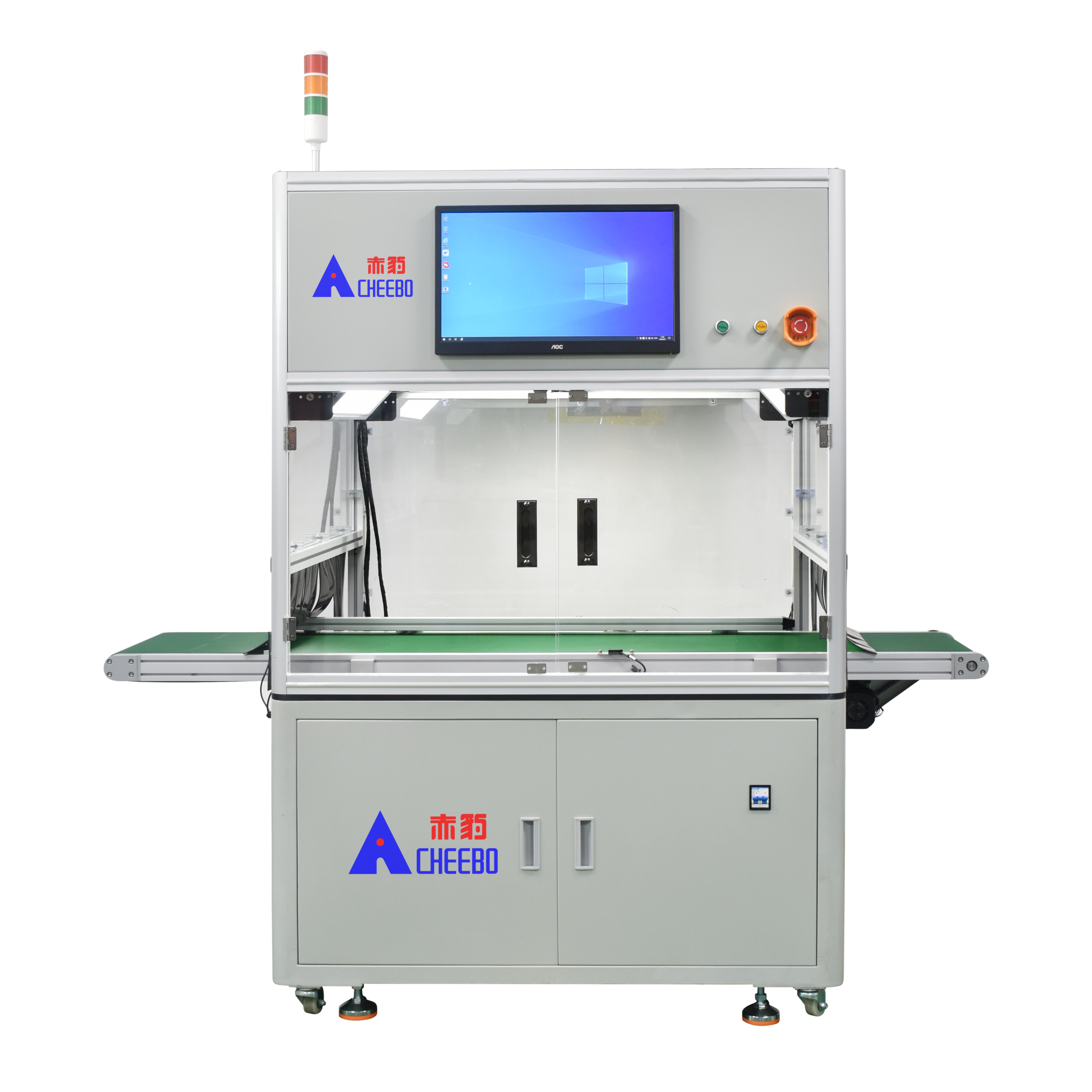

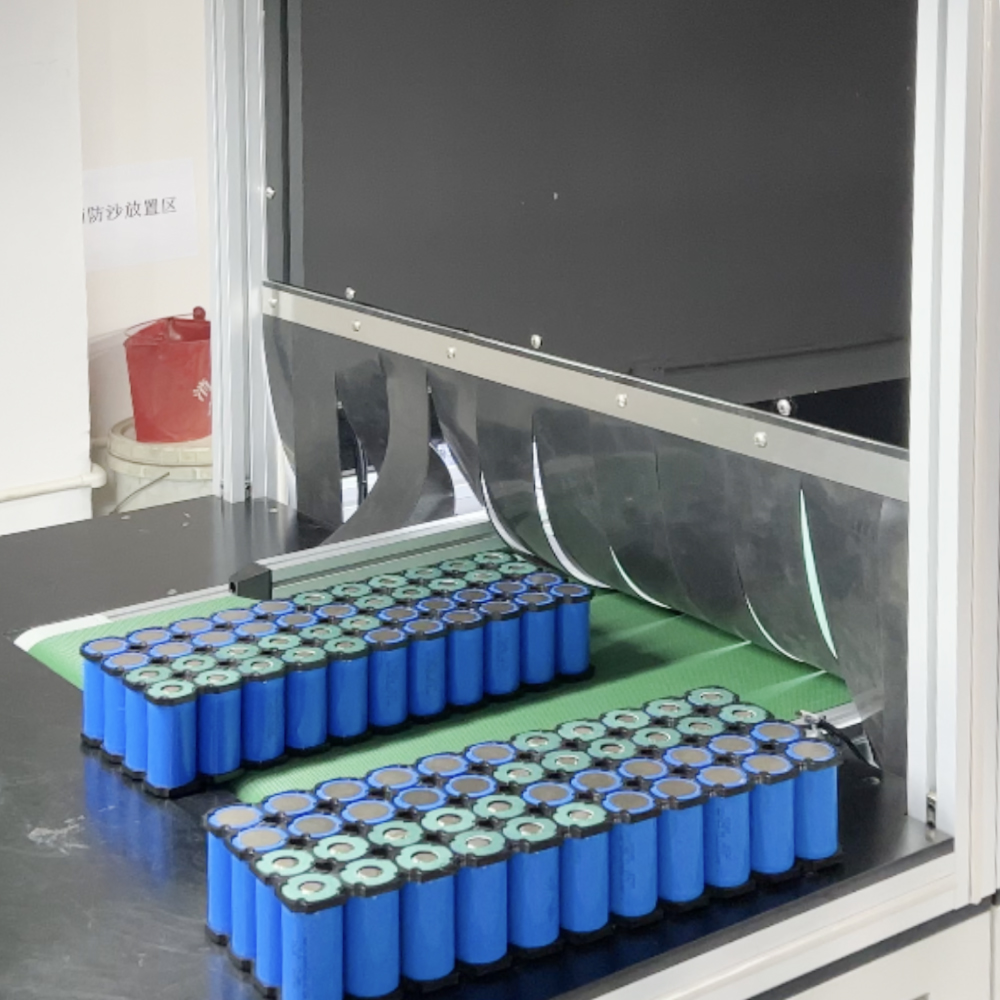

A non-contact detection, ultra-fast response and automatic elimination device for recording quality data – the core equipment.

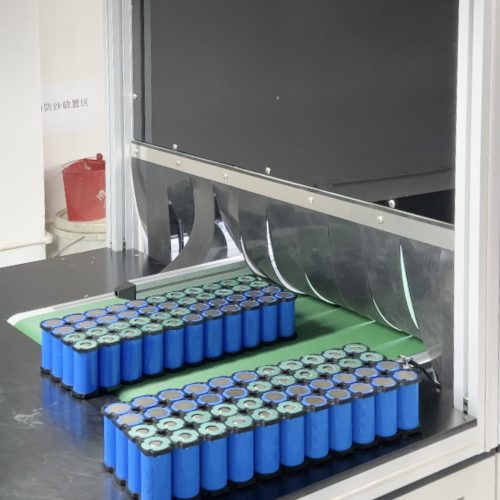

●High-precision error prevention: The system is equipped with multiple verification mechanisms, and automatically eliminates or alarms and stops any polarity errors or unidentifiable batteries.

● Non-contact detection: Non-contact optical detection, without physical wear and tear, suitable for high-speed production cycles, seamlessly integrated into automated production lines.

●Intelligent management: Equipped with a human-machine interface, it can display real-time information such as the number of tests, pass rate, error alerts, etc., and parameter adjustments are convenient.

- The CCD visual inspection equipment adopts machine vision technology and is a multi-purpose visual inspection system based on CCD industrial cameras for inspection.

- Compatible with multiple specifications of battery packs, supports multi template comparison, and can store 100 sets of test data.

- Belt transmission, fast detection without lagging, saves labor costs, and can perform highly repetitive work.1000W high-definition camera with zero detection error, stable operation for a long time, good reliability, and high detection accuracy.

- It has manual debugging function, which can fine tune and save monitoring area parameters for each detection, as well as adjust the overall offset function.

- Equipped with automatic fixture positioning detection, capable of determining OK/NG and counting quantities.

- Designed with adjustable lighting height, it can be used in various lighting environments.

Technical Specs details presentation

| Main technical specifications | |

| Detection range | 250*400MM(Customizable) |

| Detection efficiency | 6-8PPM |

| Detection algorithm | Contrast |

| Lens pixels | 2000W pixel high-definition lens |

| Transmission mode | Belt transmission |

| Display mode | graphic display |

| Size weight | 1200*1000*1800mm 230KG |

| Power | 220V 50/60HZ |

CCD Visual Inspection

Utilizing a 20-megapixel Hikvision industrial camera, it delivers high detection accuracy and supports multi-type defect recognition including polarity, missing parts, and misalignment.

Non-contact detection

No need to touch the battery cells, avoiding damage to the products. Safe and reliable, suitable for high-quality production lines.

Intelligent alarm

Automatic audible and visual alarm + graphical positioning during NG situation. After manual confirmation, it can be released, improving the efficiency of error correction.

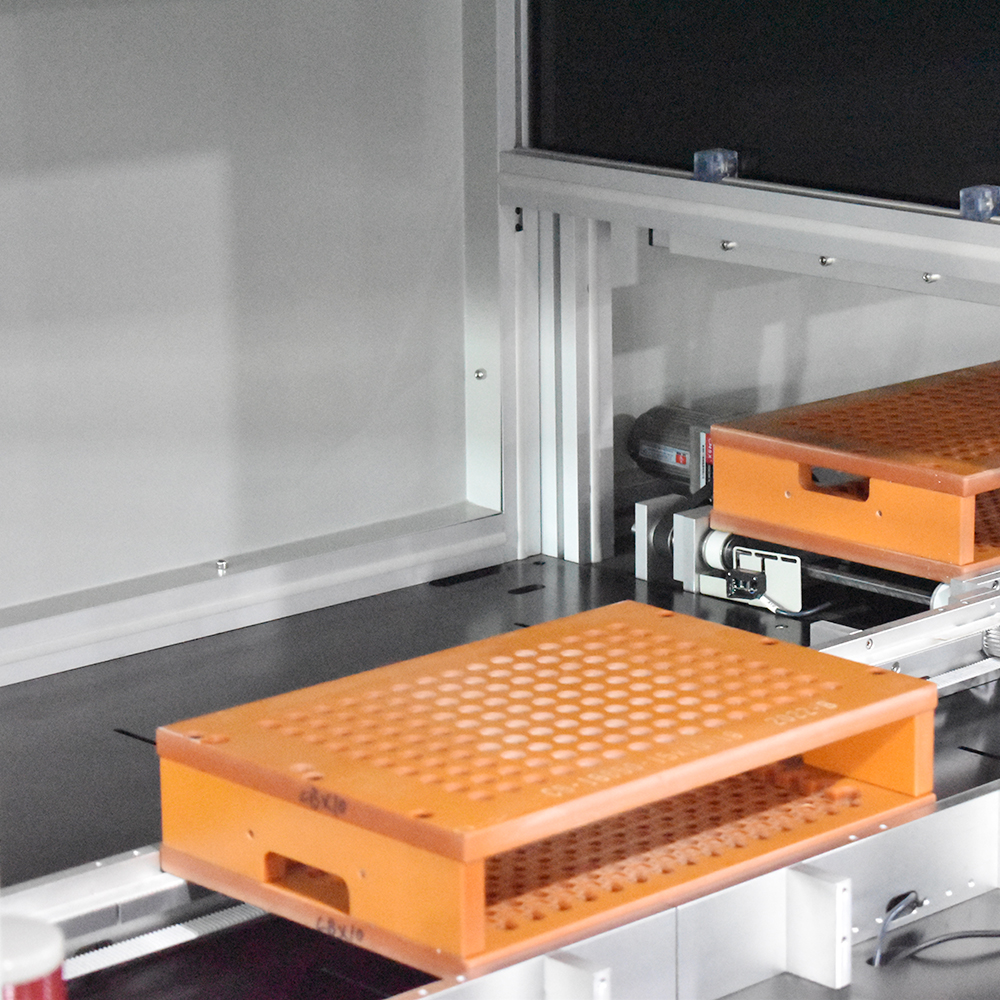

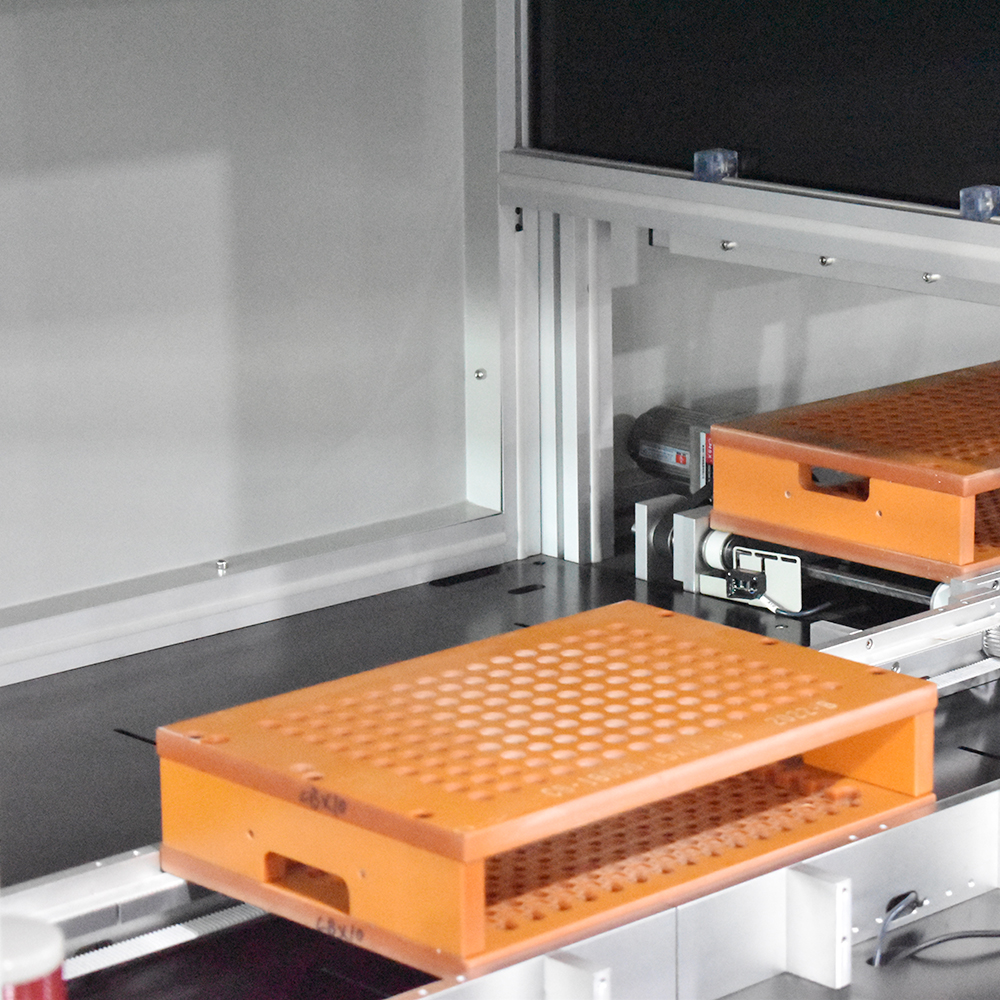

Belt line design

Left-in-right-out assembly line layout, supporting fixture reflow, seamless connection between front and rear production lines.

Reviews

There are no reviews yet.