Description

Equipment Description:

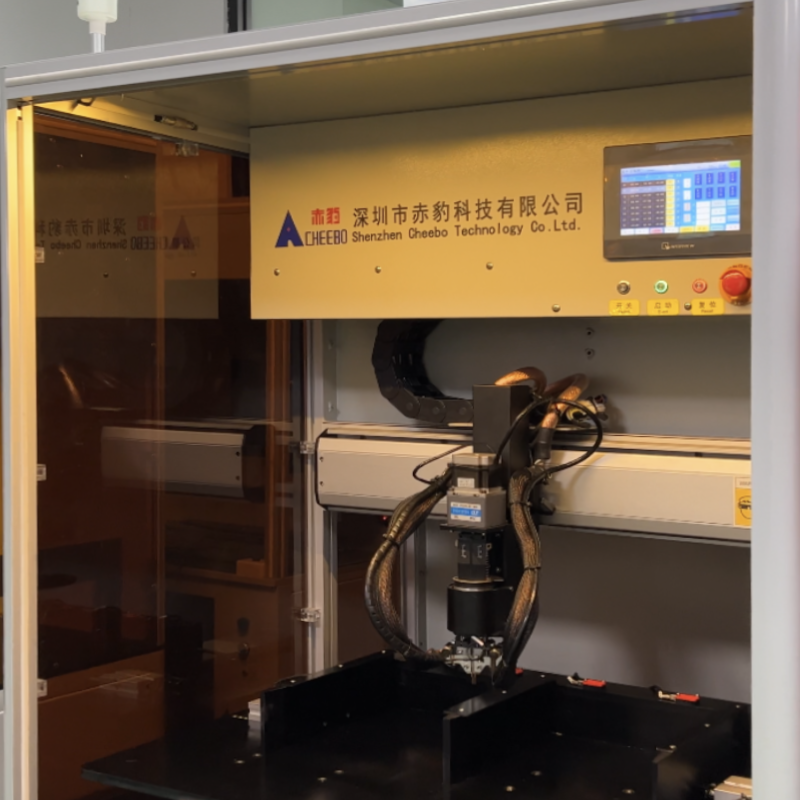

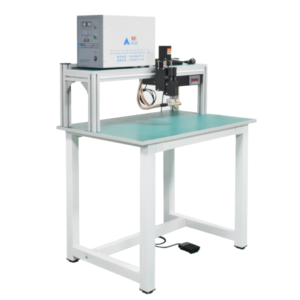

A high-precision, highly automated lithium battery welding equipment specially designed for the production of high-end battery packs.

● High precision: The servo multi-axis system guarantees that the position of the solder joints and the welding pressure are spot-on accurate.

● High reliability: Based on an overall design with profound experience, the equipment has a low failure rate and operates stably over an extended period.

● High safety: Precise control prevents battery damage and reduces safety risks caused by poor welding.

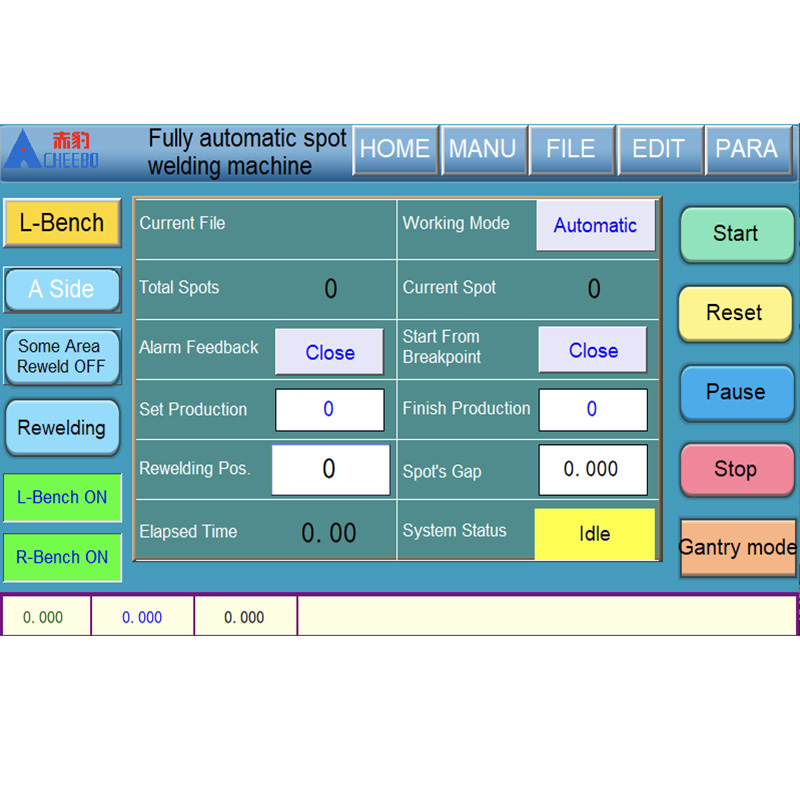

- It can work on both left and right platforms without interfering witheach other, or only use a single platform.

- Suitable for nickel plating process BMs welding, one machinedual-use.

- 135 °electric precision rotating welding head, suitable for variousshaped nickel sheets, with anti sticking needle function.

- Explosion welding and weak welding equipment automatically alarm,manual adjustment of automatic area welding repair, single pointwelding repair.

- Manual programming, CAD mapping, importing spot welding paths,easy to learn and quicklyimplement programming.

- Independently develop various automated intelligent systems tofacilitate device operation and help improve production efficiency.

- lmported acrylic protective board, beautiful and stylish with strongtechnological sense, visual operation improves production safetyfactor.

Technical Specs

| Equipment Capacity | 30-40PPM |

| Compatible Battery | 18650/21700/26650/32700/32140 |

| Compatible Modules | <600*400MM(Customizable) |

| Welding Thickness | 0.02-0.3MM |

| Repositioning Accuracy | ±0.01 |

| Welding Head Rotation Angle | 0~135° |

| Welding Power Source | Transistor/Multi pulse |

| Weld Pressure | 5KG/F(Adjustable) |

| Cooling Method | Water circulation cooling |

| Driving Method | pneumatic |

| Size Weight | 1400*1000*1680MM 380KG |

| Power | 220V 50/60HZ |

Details presentation

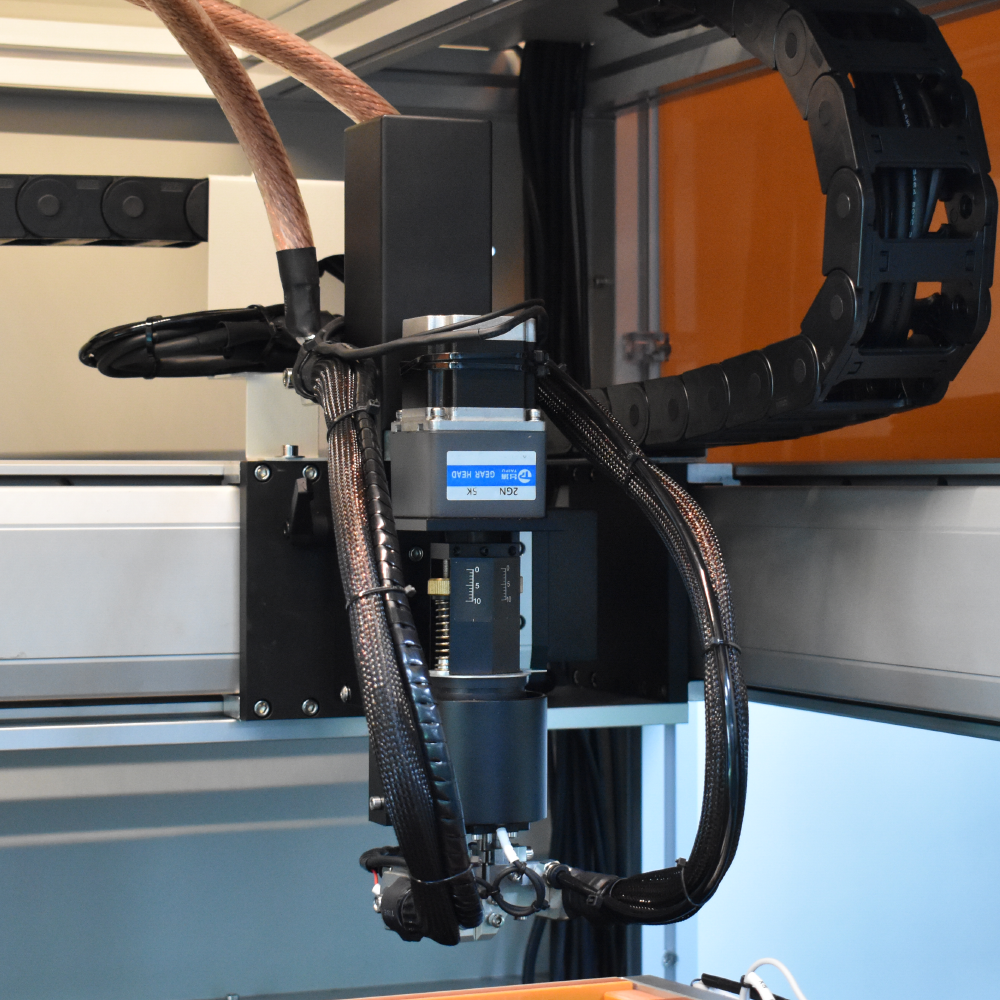

High-Precision Rotating Welding Head

Our independently developed 135° rotating welding head is ideal for welding irregular nickel plates. Pure nickel construction prevents needle sticking. Welding pressure is precisely adjustable via a buffer spring pressure adjustment mechanism, effectively minimizing damage to battery cells.

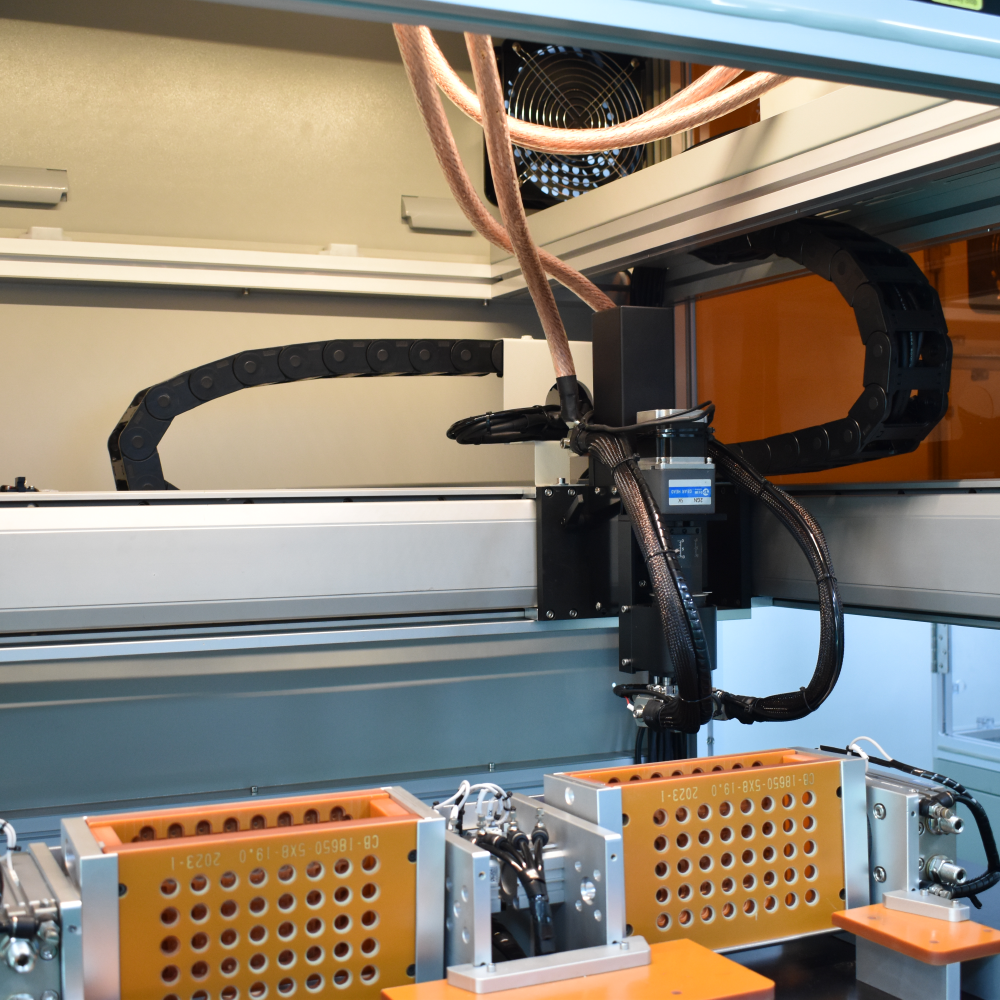

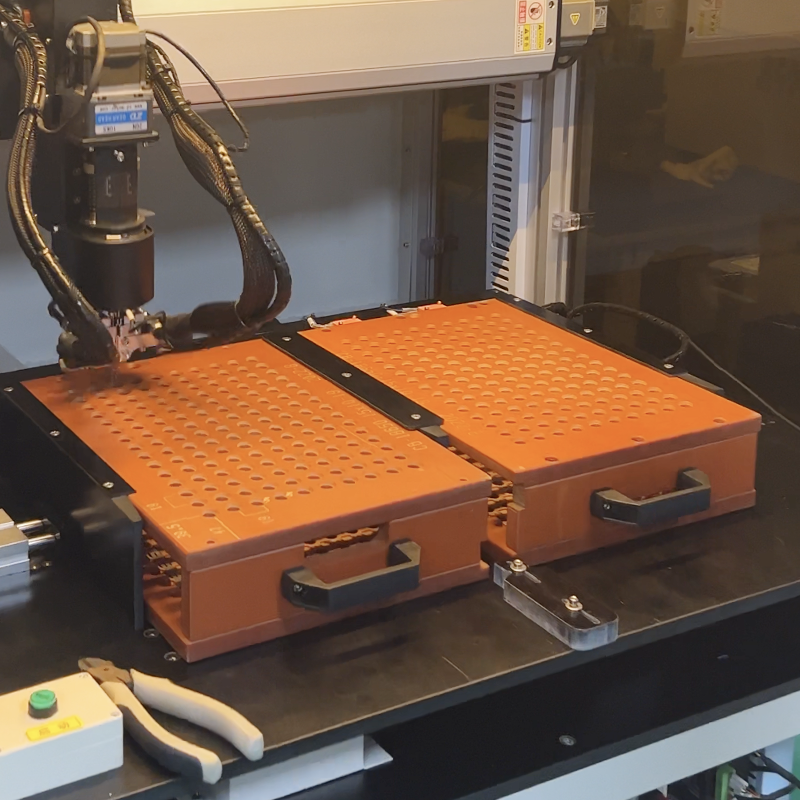

Dual-platform independent operation

Left and right platforms can run simultaneously or independently without interference, supporting non-stop material changeover for high production efficiency.

Mandatory water circulation cooling system

The welding head is connected to the water pipe for circulation cooling to prevent the welding head from overheating during long-term welding, which would affect the welding quality.

Intelligent Programming Operation

Supports CAD path import, manual programming, and computer programming. Stores up to 190 welding recipes for flexible and efficient operation.

Reviews

There are no reviews yet.