Description

Customizable Copper Brazing Rod

,

Copper Brazing Rod C15760

,

Copper Rod For Welding C15760

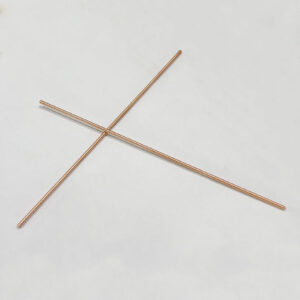

Spot Welding Needle 3.0*100*2.0MM Battery Pack Welding Special Welding Needle

● Suitable for spot welding between materials such as nickel strip, nickel infiltrated steel sheet, and coated steel strip in battery production. In the production of nickel gas batteries, nickel pot batteries, polymer batteries, lithium batteries, and other batteries, spot welding of connecting pieces, cells, and lead-out pieces is necessary.

● Product name: Aluminum oxide copper spot welding needle, butt welding needle

● Material: Domestic material, Taiwanese material, Japanese material, American material

● Needle models: eccentric flat head, eccentric ball head, same core ball head, straight baseball head, straight rod, other customized

● All welding needles produced by our manufacturer are made of aluminum oxide copper material

● Electric resistance welding material – nano alumina dispersion strengthened copper (alumina copper)

● Aluminum oxide copper – specially designed for spot welding of galvanized steel plates, nickel plated plates, nickel strips, aluminum alloys, stainless steel, brass, and other materials

● Aluminum oxide copper material is resistant to softening and erosion, with a long service life and high spot welding frequency. The electrode life is more than 5 times that of ordinary chromium zirconium copper, reducing the time for stopping work and grinding the electrode

● The battery spot welding machine adopts aluminum oxide copper material welding needles, which improves the efficiency of automatic welding production lines. When welding coated metal, the electrodes are not bonded, providing a terminal solution for the welding of galvanized steel plates. It is an indispensable electrode material for welding galvanized steel plates, nickel plates, nickel strips, aluminum alloys, stainless steel, brass, and other essential electrode materials.

● The softening temperature of aluminum oxide copper welding needle can reach 930 ℃, making it a relatively high alloy in copper. The conductivity can reach 85% IACS, with high strength and good wear resistance.

● The conductivity can reach 85% IACS, and the heat dissipation performance is between tungsten copper (220 W/m.k) and pure copper (390 W/m-k).

● The softening temperature can reach 930 ℃, which is relatively high among copper alloys, but lower than tungsten copper (1000 ℃)

- Avoid sticky electrode phenomenon

- No yellowing of the welding area, beautiful welding joints

- Avoid the occurrence of false welding phenomenon

- Reduce the phenomenon of welding sparks

- Excellent electrical and thermal conductivity and good high temperature performance

- Passed the EU ROHS environmental certification standard

| Place of origin | Guangdong, China | Processing customization | Yes |

| Operating temperature | 25℃ | Type | Through/Eccentric/convex (optional) |

| Model number | C15760 | Length | 100MM (customizable) |

| Melting point | 930℃ | Diameter | 1.7MM (customizable) |

| Material | Aluminum oxide copper | Scope of application | Metal welding |

| Model | Al2O3 content(wt%) | HRB | Electrical conductivity(%lACS) | Strength of extension(MPa) |

| C15715 | 0.3 | 65 | 94 | 480 |

| C15740 | 0.6 | 74 | 85 | 540 |

| C15760 | 1.1 | 85 | 80 | 620 |

1. Seiko Production

Deep processing, smooth surface, stable welding point without virtual welding, solid welding point

2. High quality material

imported alumina copper material is more wear resistant to burning, longer service life

3. Professional customization

Years of processing experience combined with the actual situation of customers to meet customer customization requirements

Reviews

There are no reviews yet.